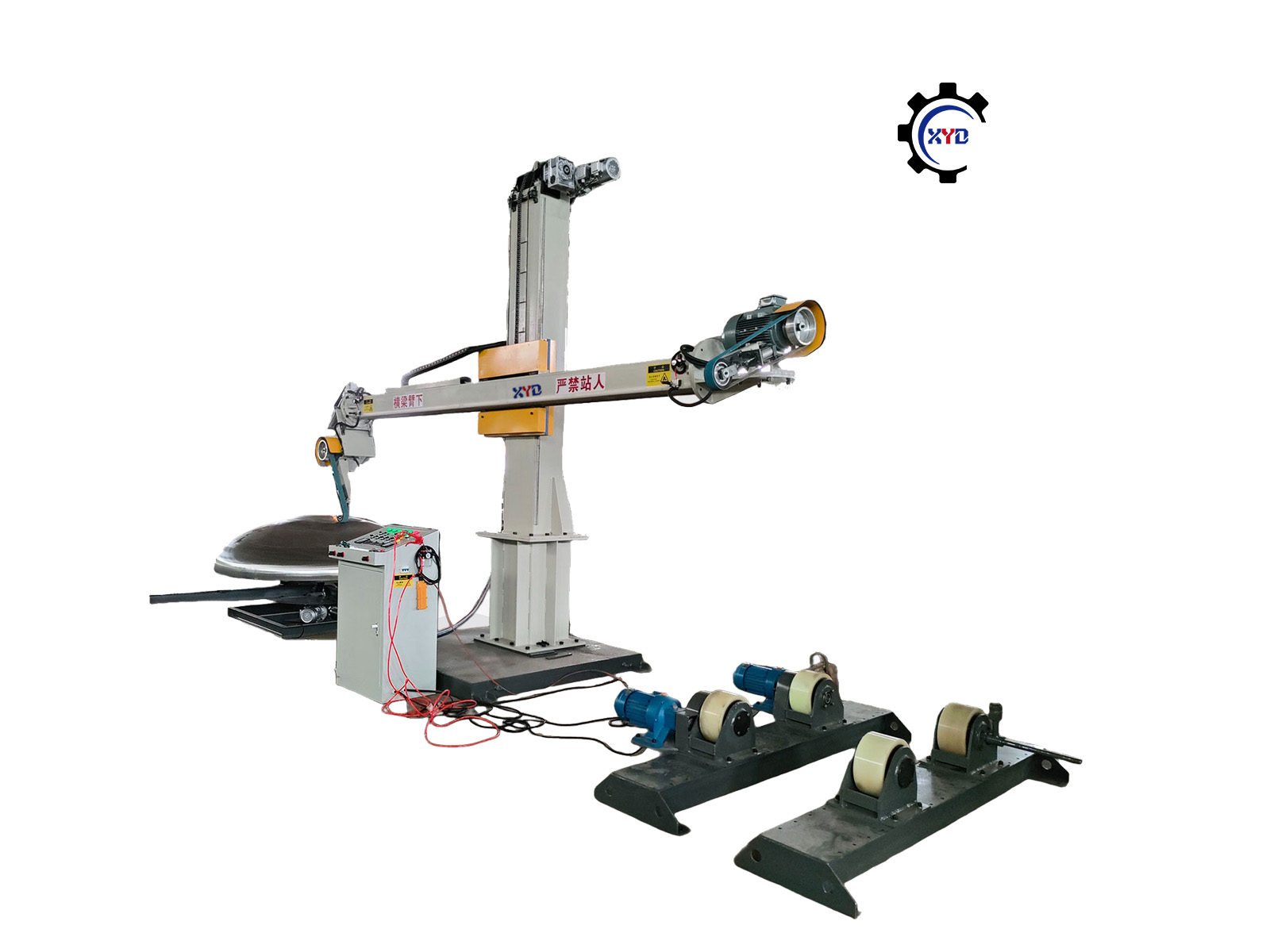

3-Axis CNC polishing machine

Publish time:2022-02-27 15:18:58 Popularity:0 Source:未知来源

1. Product Overview

The 3-Axis CNC Wet Polishing Machine is a smart and eco-friendly polishing system designed for stainless steel tanks, chemical containers, and food-grade equipment. With servo-controlled beam, polishing head, and rotary table, it provides full automation and precision in surface treatment. The integrated wet polishing process with water circulation cooling and dust elimination ensures a clean and sustainable working environment, fully compliant with environmental protection standards. Ideal for industries requiring high surface quality and minimal dust emission.

2. Key Features

| Feature | Advantage |

|---|---|

| Full CNC Automation | Servo-driven beam and polishing head for contour-adaptive polishing |

| Wet Polishing Process | Water-cooled and dust-free operation for environmental compliance |

| Servo Rotating Head | Enhances polishing consistency and surface finishing results |

| Wide Workpiece Compatibility | Supports diameters Φ500–4000mm and lengths up to 3000mm |

| Efficient Cooling System | Water circulation filters reduce belt wear and maintenance costs |

3. Technical Specifications

1. Workpiece Capacity

| Parameter | Value |

|---|---|

| Diameter Range | Φ500–4000mm |

| Vertical Polishing Length | 0–3000mm |

| Inner Surface Depth | 0–800mm |

2. Power System

| Component | Specification |

|---|---|

| Polishing Head Motor | 7.5kW High Torque |

| Sanding Belt Size | 2500×50mm |

| Turntable Motor | 3kW |

| Turntable Speed | 1–20rpm (Variable Frequency) |

3. Polishing Efficiency & Process

-

Wet polishing reduces dust, extends belt life

-

Optimized CNC motion paths for high surface finish

-

Effective polishing rate: 6–10㎡/h

4. Eco-Friendly Design

-

Water circulation for cooling and dust removal

-

Zero-dust operation, meeting national environmental regulations

4. Application Scope & Industries

Suitable Workpieces:

-

Cylindrical bodies, tank heads, cones, and welded assemblies

-

Surface finishes: matte, glossy, mirror

-

Ideal for complex curved surfaces with contour-matching polishing

Target Industries:

-

Stainless steel tank production

-

Chemical container finishing

-

Food and pharmaceutical machinery

-

Pressure vessel post-treatment

-

Cleanroom and eco-friendly workshops

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service