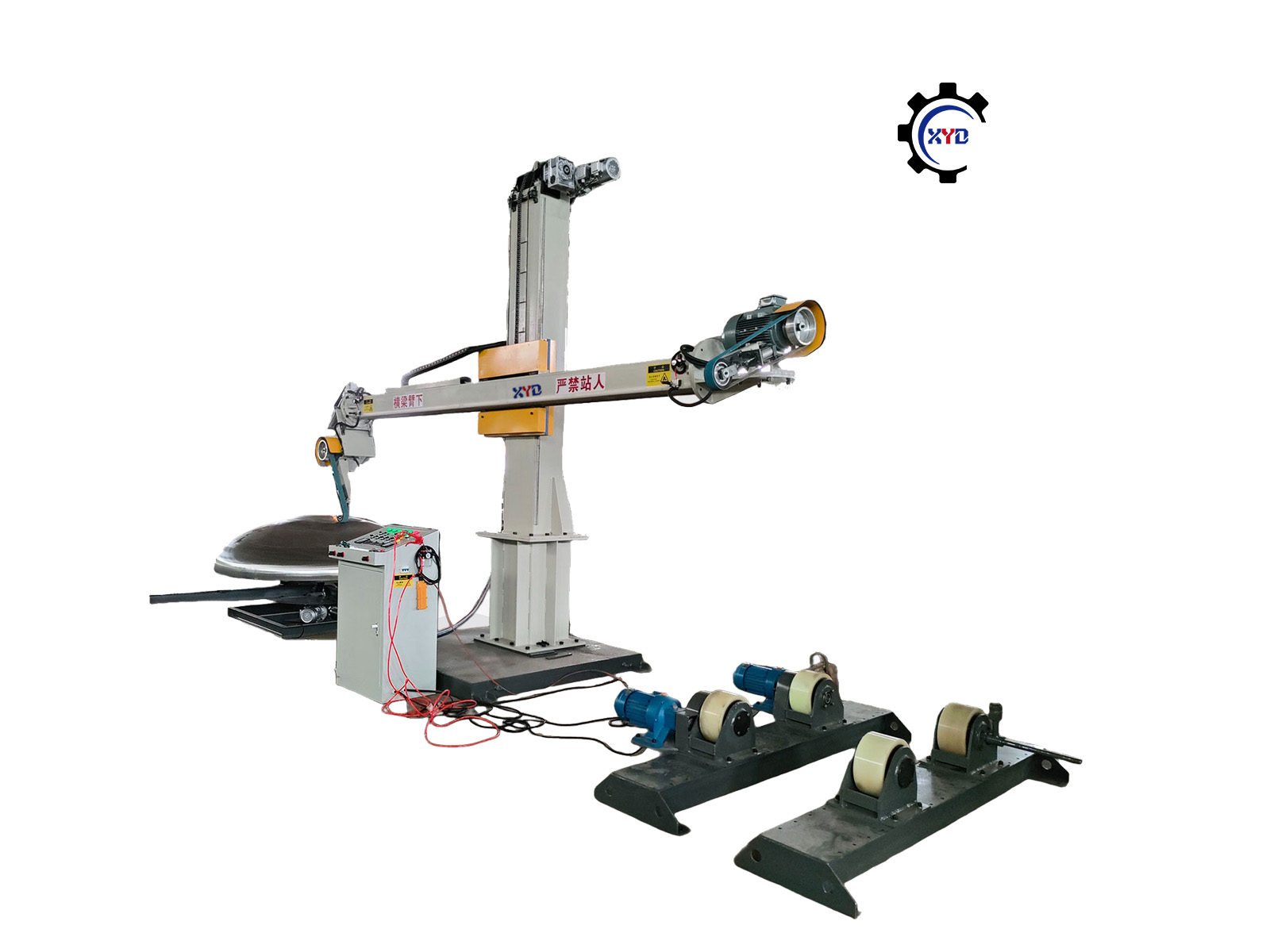

Dished end polishing machine -2000

Publish time:2025-07-31 17:45:32 Popularity:0 Source:未知来源

1. Overview

The XYD-CNC (JY-CNC) CNC dished end polishing machine is a fully automatic system designed for polishing concave metal heads, end caps, and vessel ends with high efficiency and precision. Engineered for elliptical surfaces of stainless steel, carbon steel, and alloy materials, this machine integrates servo control, automatic pressure adjustment, pneumatic self-centering clamping, and a fully enclosed visible safety cover. It is widely applied in pressure vessel manufacturing, food-grade tank production, and pharmaceutical equipment finishing.

2. Product Features

| Feature | Description & Benefits |

|---|---|

| Servo Control System | One-touch operation, smooth and consistent results |

| Intelligent Pressure Control | Imported sensor for automatic polishing pressure |

| Pneumatic Auto-Centering | Fast and precise clamping of complex workpieces |

| Fully Enclosed Cover + Window | Safe, dust-free environment with real-time visibility |

| Optional Dust Collector | Improves workshop cleanliness, supports eco standards |

3. Technical Specifications

| Specification | Details |

|---|---|

| Model | XYD-CNC (JY-CNC) |

| CNC System | Siemens / HNC / DNV |

| Operation Mode | Fully automatic CNC |

| Travel Stroke | 2000mm (defines maximum polishing diameter) |

| Polishing Motor | 4kW or 5.5kW (Brand: WANNA) |

| Spindle Speed | 2800 RPM high-speed polishing |

| Inverter Brand | ZhongChen / DELTA / DNV |

| Electrical Components | Schneider Electric |

| Polishing Tools | Compatible with replaceable belts and wheels |

4. Processing Scope & Applications

| Capability | Description |

|---|---|

| Diameter Range | 400–2000mm elliptical concave heads |

| Max Workpiece Height | Up to 800mm |

| Suitable Workpieces | Vessel heads, lids, end caps, round end plates |

| Surface Polishing Area | Inner/outer shell of concave heads |

| Surface Finish | Matte / Gloss / Mirror (Ra ≤ 0.2μm) |

| Productivity | 10–12㎡/hour (up to 15㎡/h) |

| Compared to Traditional | 87% higher productivity (vs. 5–8㎡/h) |

Application Fields:

-

Stainless steel tank head polishing

-

Food equipment end cap surface finishing

-

Pharmaceutical container lid polishing

-

Chemical reactor cover treatment

-

Pressure vessel head grinding and polishing

-

End weld seam surface finishing

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service