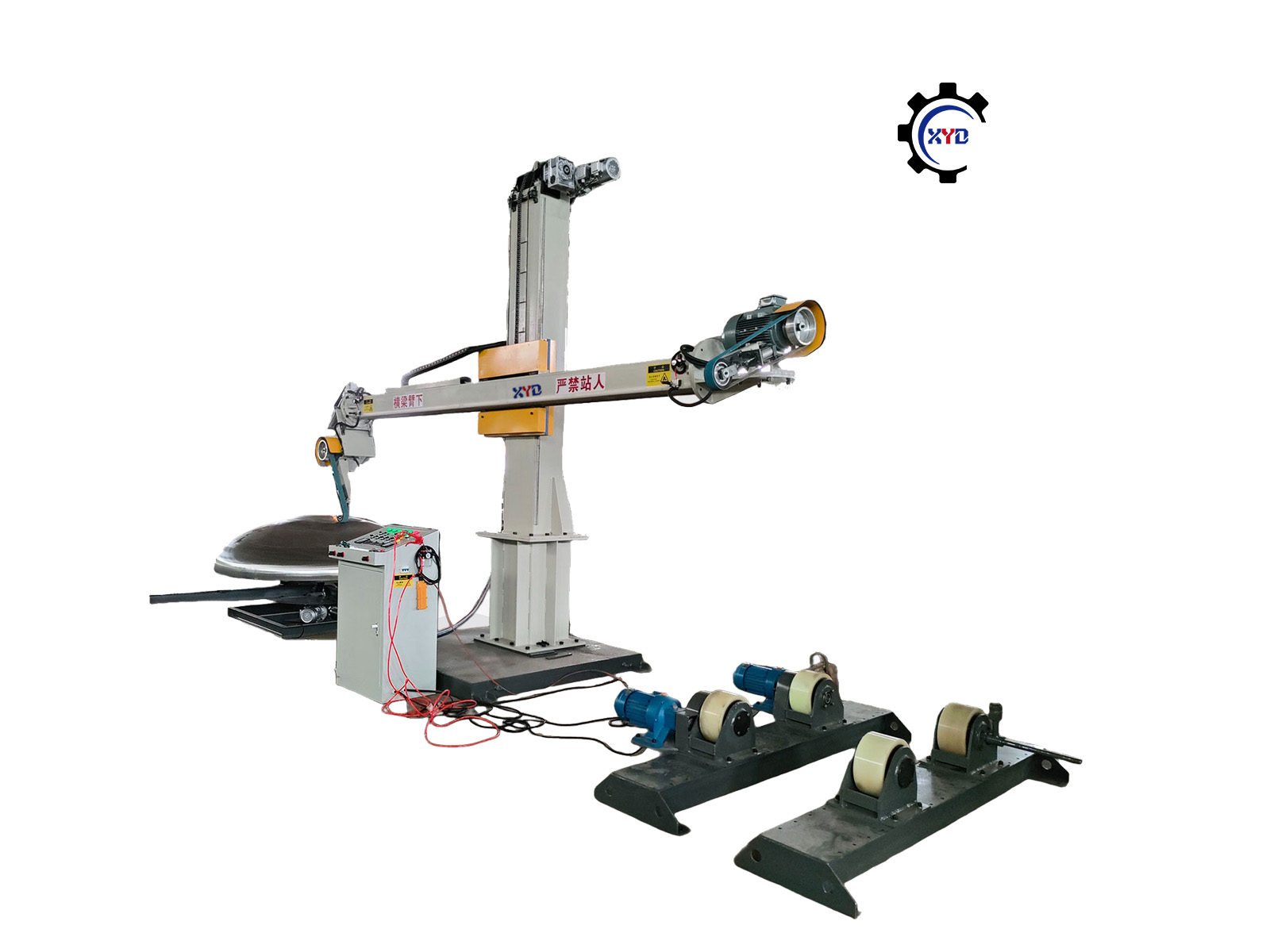

Reduction furnace CNC polishing machine

Publish time:2024-03-01 11:30:40 Popularity:0 Source:未知来源

1. Product Overview

The XINYIDA vertical vessel inner wall polishing system is engineered to address the challenges of polishing large, upright pressure vessels and reaction tanks that cannot be horizontally placed. Designed for workpieces φ1500–3500mm × up to 4000mm high, the machine features a dual servo polishing head, intelligent constant-pressure control, and pneumatic auto-centering, ensuring precision, safety, and 30%+ efficiency boost. It is ideal for pharmaceutical, chemical, and environmental equipment applications.

2. Product Features

| Feature | Advantage Description |

|---|---|

| Dual Servo Polishing Head | Two heads work simultaneously for 30%+ efficiency boost; single-click start/stop |

| Constant Pressure System | Imported sensors maintain polishing pressure automatically with zero manual control |

| Pneumatic Centering Clamp | Auto-aligns the vessel within ±0.5mm accuracy, increasing clamping speed by 50% |

| Full Enclosed Chamber | Transparent window for real-time monitoring; optional dust collection system available |

| Column Rotating System | Workpiece stays static; rotating column ensures 360° polishing coverage |

3. Technical Specifications

| Parameter | Specification |

|---|---|

| Suitable Workpieces | Reaction tanks, vertical vessels (inner shell + dish end) |

| Workpiece Size | Φ1500–3500mm × max height 4000mm |

| Polishing Media | Flap wheel, cloth wheel, and other consumables |

| Motion System | Frequency-controlled column rotation + 3D adjustable head |

| Safety Features | Full enclosure with emergency stop and dust collection ports |

4. Application Scope

| Industry Sector | Typical Workpieces |

|---|---|

| Pharmaceutical | Aseptic tanks, bioreactors |

| Chemical Equipment | Pressure reactors, jacketed vertical vessels |

| Environmental Sector | Sludge storage tanks, chemical waste containers |

| Insulated Containers | Inner wall polishing of large, stationary, jacketed tanks |

Core Value: Effectively solves polishing issues for large vertical vessels that cannot be rotated or laid down, particularly in clean and precision-demanding industries.

Return to List About News

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Online Service

Contact information

QR code

Online Service

QQ Customer Service

QQ Customer Service