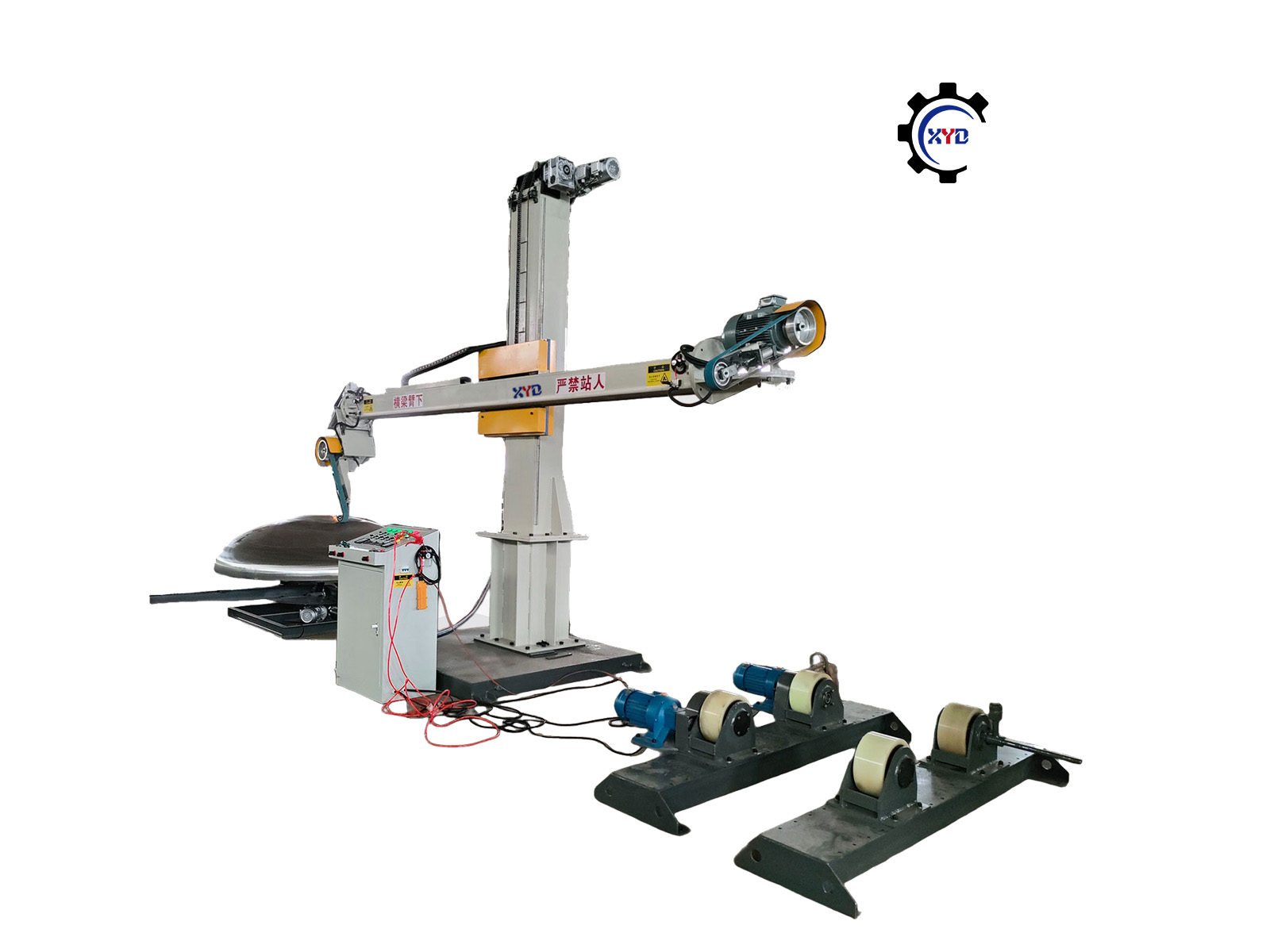

Dished end polishing machine -3000

Publish time:2024-03-01 09:56:32 Popularity:0 Source:未知来源

1. Product Overview

The CNC dish end polishing machine (3-meter model) is specially designed for high-precision surface finishing of large elliptical heads, concave ends, and stainless steel components. Featuring dual servo polishing heads, intelligent pressure control, automatic centering clamping, and optional dust collection, it delivers an automated, efficient, and eco-friendly solution ideal for pressure vessels, food processing equipment, and pharmaceutical containers.

2. Core Features

| Feature | Technical Advantage |

|---|---|

| Dual Servo Head System | Dual polishing heads operate simultaneously, increasing efficiency by 30%+, one-button start/stop |

| Intelligent Pressure Control | Imported sensors maintain constant pressure without manual adjustment |

| Pneumatic Auto-Centering | Rapid and precise clamping within seconds, increasing clamping speed by 50% |

| Fully Enclosed Design | Splash-proof shield with visual windows and optional dust collection system |

| High-Efficiency Belt | 50mm wide, 52.4m long belt supports up to 20㎡/h grinding rate |

3. Technical Specifications

| Item | Value |

|---|---|

| Model | Custom 3-Meter CNC Head Polisher |

| Dimensions | 4300×3400×3950mm (L×W×H) |

| Weight | 5800 kg |

| Power System | 2×4kW Dual Motor Drive |

| Head Speed | 2800 RPM (High-Speed Precision Grinding) |

| Sanding Belt | 52400×50mm |

| Polishing Capacity | 12–20㎡/h |

| Clamping System | High-precision lead screw + pneumatic centering |

4. Working Range & Applications

-

Working Range:

-

Max Head Diameter: ≤3000mm

-

Supports outer shell and inner concave polishing

-

Surface Finish Options: Matte / Bright / Mirror

-

-

Application Areas:

-

Pressure vessel manufacturing (e.g., enamel reactors, stainless tanks)

-

Food and pharmaceutical-grade equipment surface finishing

-

Chemical & environmental tanks

-

Precision stainless steel structures

-

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service