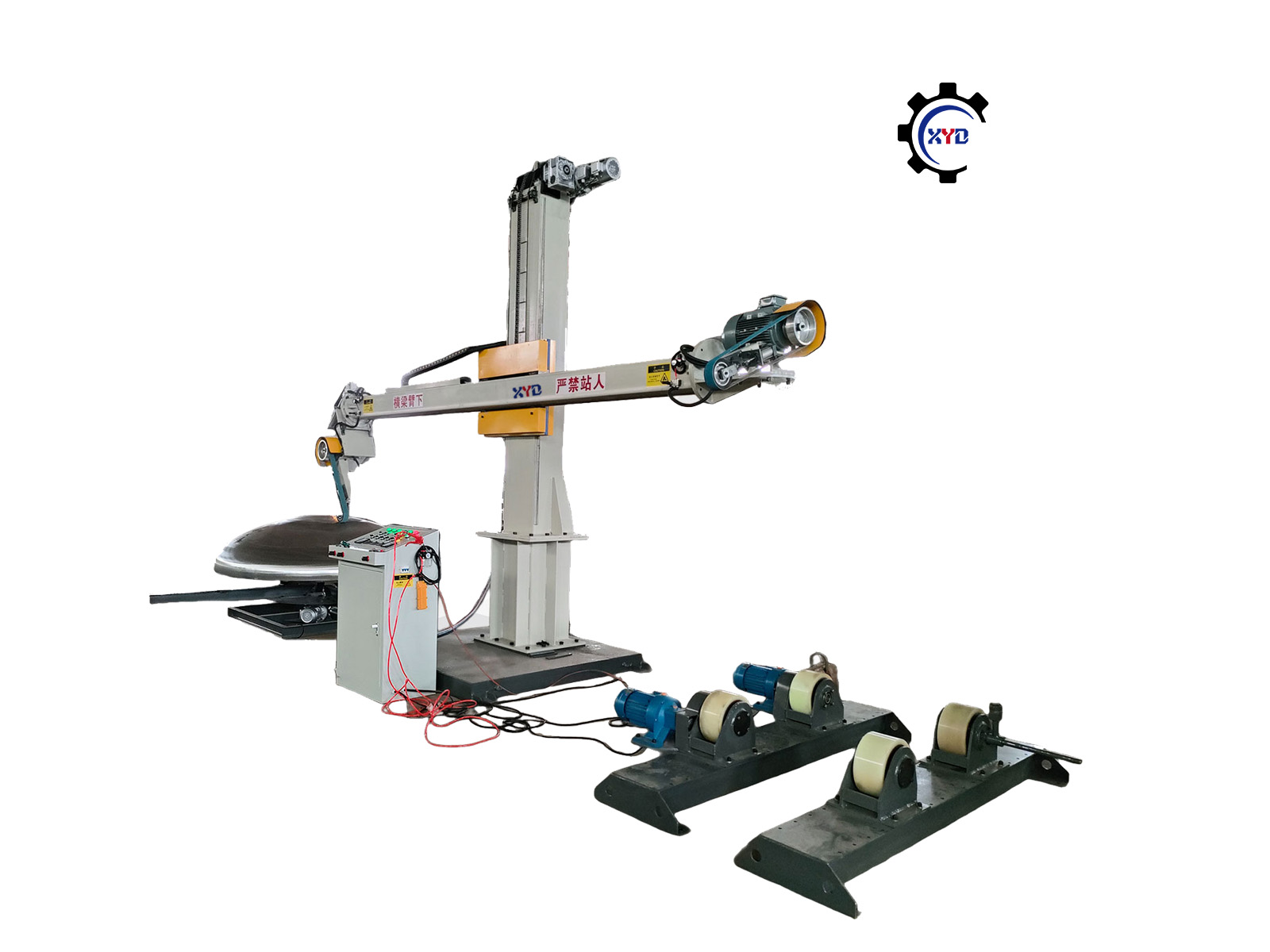

Tank & Dished end Polishing Machine-PCL3000

The XinYida XYD-2 PLC Integrated Dished Head and Tank Polishing Machine is specifically designed for the automatic precision polishing of stainless steel dished head inner surfaces and tank outer surfaces. It is suitable for dished heads with diameters from φ500 mm to φ3000 mm and tanks from φ800 mm to φ3000 mm.

Tank & Dished end Polishing Machine XYD-3000PLC

- Introduction

- Video

1. Product Overview

The XinYida XYD-2 PLC Integrated Dished Head and Tank Polishing Machine is specifically designed for the automatic precision polishing of stainless steel dished head inner surfaces and tank outer surfaces. It is suitable for dished heads with diameters from φ500 mm to φ3000 mm and tanks from φ800 mm to φ3000 mm.

Based on the JY-2HH dished head polishing machine, it adopts a servo motor system and upgrades the original manual control console to a PLC touchscreen control system, enabling fully automatic curved surface grinding and polishing.

This machine not only reduces reliance on operator skill levels, but also improves production efficiency and polishing consistency, ensuring stable product quality. It is particularly suitable for equipment manufacturing in the food, pharmaceutical, chemical, and high-purity industries.

2. Product Features

| Feature Category | Description |

|---|---|

| Applicable Range | Dished head diameter: φ500–3000 mm; Tank diameter: φ800–3000 mm |

| Automation Control | PLC program control + HMI touchscreen; supports parameter recipe storage and recall |

| Precision Drive | Servo motor system + frequency inverter control for smooth operation and high positioning accuracy |

| Programmability | Configurable multi-segment grinding paths (up to 5 points) and interpolation speed, enabling multi-line fitting for curved surfaces |

| Stability & Consistency | Automatic operation reduces human variability, ensuring stable quality in batch production |

| Brand Components | Xinje PLC and servo system, Schneider switches and components for durability and reliability |

3. Technical Specifications

| Item | Parameter |

|---|---|

| Model | XYD-2 |

| Processing Diameter Range | Dished head: φ500–3000 mm; Tank: φ800–3000 mm |

| Processing Depth | ≤1000 mm |

| Maximum Load | Standard: 1 ton; Optional: up to 20 tons |

| Control System | Xinje PLC + 10" touchscreen |

| Drive Method | Xinje servo motor + frequency inverter |

| Positioning Accuracy | 0.1 mm/s (zero-return positioning improves repeatability) |

| Operation Mode | Fully automatic curved surface polishing |

| Polishing System | Quick-change for sanding belt (2000×50 mm), flap wheel (φ250×50 mm), sisal wheel, and cloth wheel |

| Production Efficiency | Up to 8 m²/h for mirror-finish conditions |

4. Processing Range & Applications

| Application Type | Industry Segments |

|---|---|

| Food Equipment | Dished heads and tanks for dairy tanks, beverage tanks, brewing equipment |

| Pharmaceutical Equipment | Dished heads and tanks for aseptic storage tanks, bioreactors, herbal extraction vessels |

| Chemical Equipment | Dished heads and tanks for pressure vessels, reactors, stainless steel reaction tanks, large reactor weld polishing |

| New Energy Industry | Surface finishing for battery shells, cylinders, and other metal components; optional automatic loading/unloading robotic arm module (requires additional 2.5 m space) to enhance automation; electrical system compliant with CCC certification for safety and reliability |

| High-Purity Equipment | LNG storage tank dished heads and tanks, aerospace container dished heads and tanks |

| Pressure Vessel Industry | Inner surface mirror finishing for dished heads, precision outer surface polishing for tanks |

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service