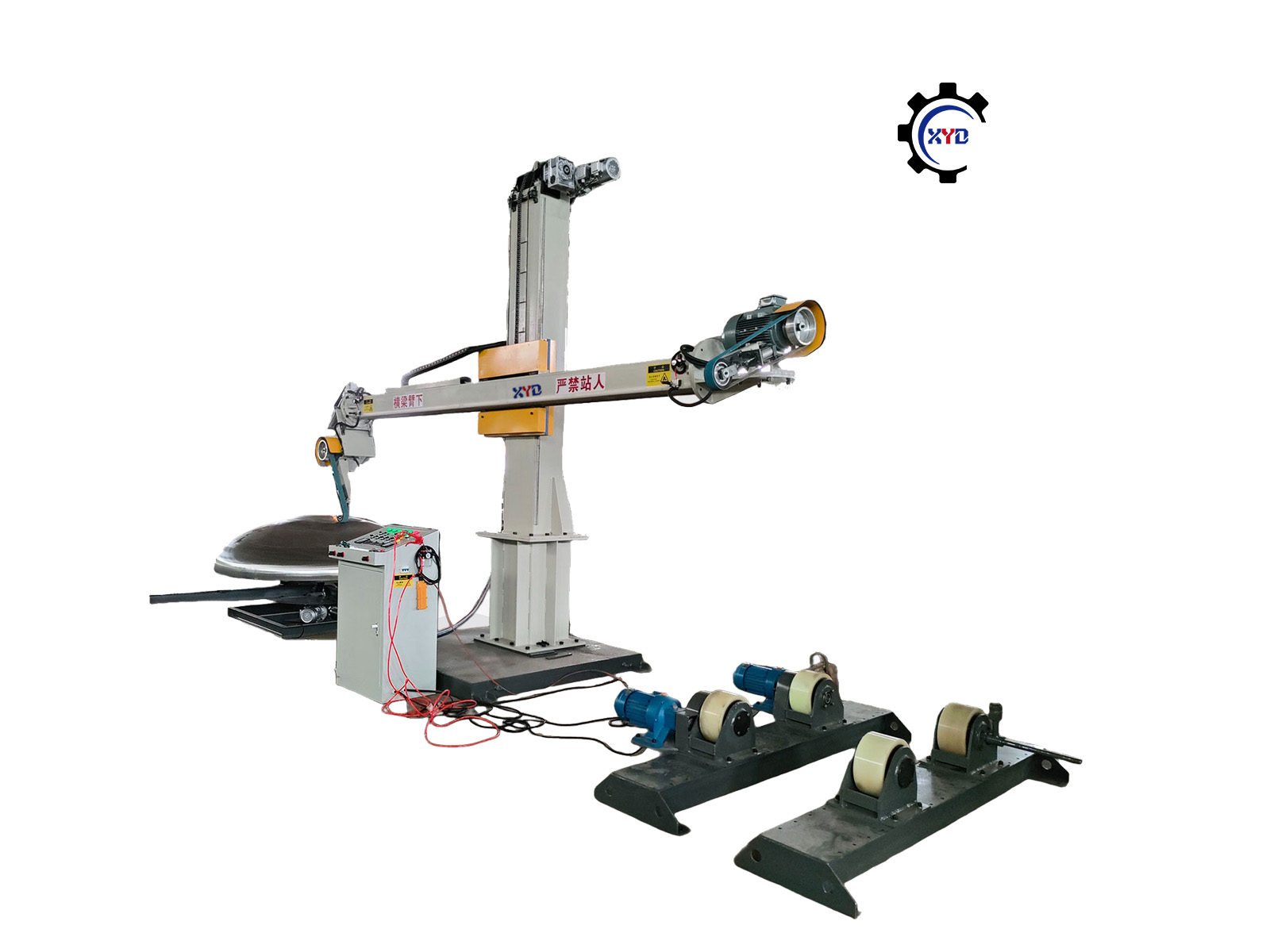

Dished end polishing machine

Publish time:2024-03-01 09:53:35 Popularity:0 Source:未知来源

1. Product Overview

The 1-meter CNC dished end polishing machine is engineered for precise surface finishing of elliptical heads, concave ends, and stainless steel components. With servo-driven automation, constant pressure polishing, and optional dust collection, it provides a highly efficient, safe, and environmentally compliant solution. This fully automatic machine is ideal for small to medium-sized workpieces in industries such as pressure vessels, precision metal processing, and pharmaceutical manufacturing.

2. Key Features

| Feature | Advantage |

|---|---|

| Servo Automatic Control | One-touch operation, high response speed, stable system |

| Intelligent Constant Pressure | Imported pressure sensor for real-time adjustment and consistent polishing force |

| Pneumatic Auto-Centering Clamping | Rapid positioning with minimal manual input |

| Fully Enclosed + Visual Window | Ensures safety, dust-proof operation, and real-time monitoring |

| Optional Dust Collection | Complies with environmental standards, ideal for cleanroom needs |

3. Technical Specifications

| Item | Value |

|---|---|

| Model | XYD-CNC (JY-CNC) |

| CNC System | Siemens / Huazhong / Delta |

| Working Mode | Full-Automatic |

| Travel Distance | 1200mm (max polishing diameter) |

| Polishing Motor | 4kW or 5.5kW (Brand: WANNA) |

| Inverter Brand | Zhongchen / DELTA / Danfoss |

| Electrical Components | Schneider Electric |

| Polishing Options | Interchangeable belts and wheels |

| Spindle Speed | 2800 RPM |

| Polishing Efficiency | 10–12㎡/h (up to 15㎡/h) |

| Workpiece Size | Elliptical ends 400–2000mm dia., height up to 800mm |

4. Working Range & Applications

-

Supported Workpieces:

-

Elliptical ends, outer and inner concave surfaces

-

Matte, glossy, and mirror finish available

-

Custom weight-bearing options

-

-

Industry Applications:

-

Polishing of stainless steel pressure vessels

-

Food and pharmaceutical-grade surface finishing

-

Precision metal component polishing

-

Smoothing of welds in chemical equipment

-

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service