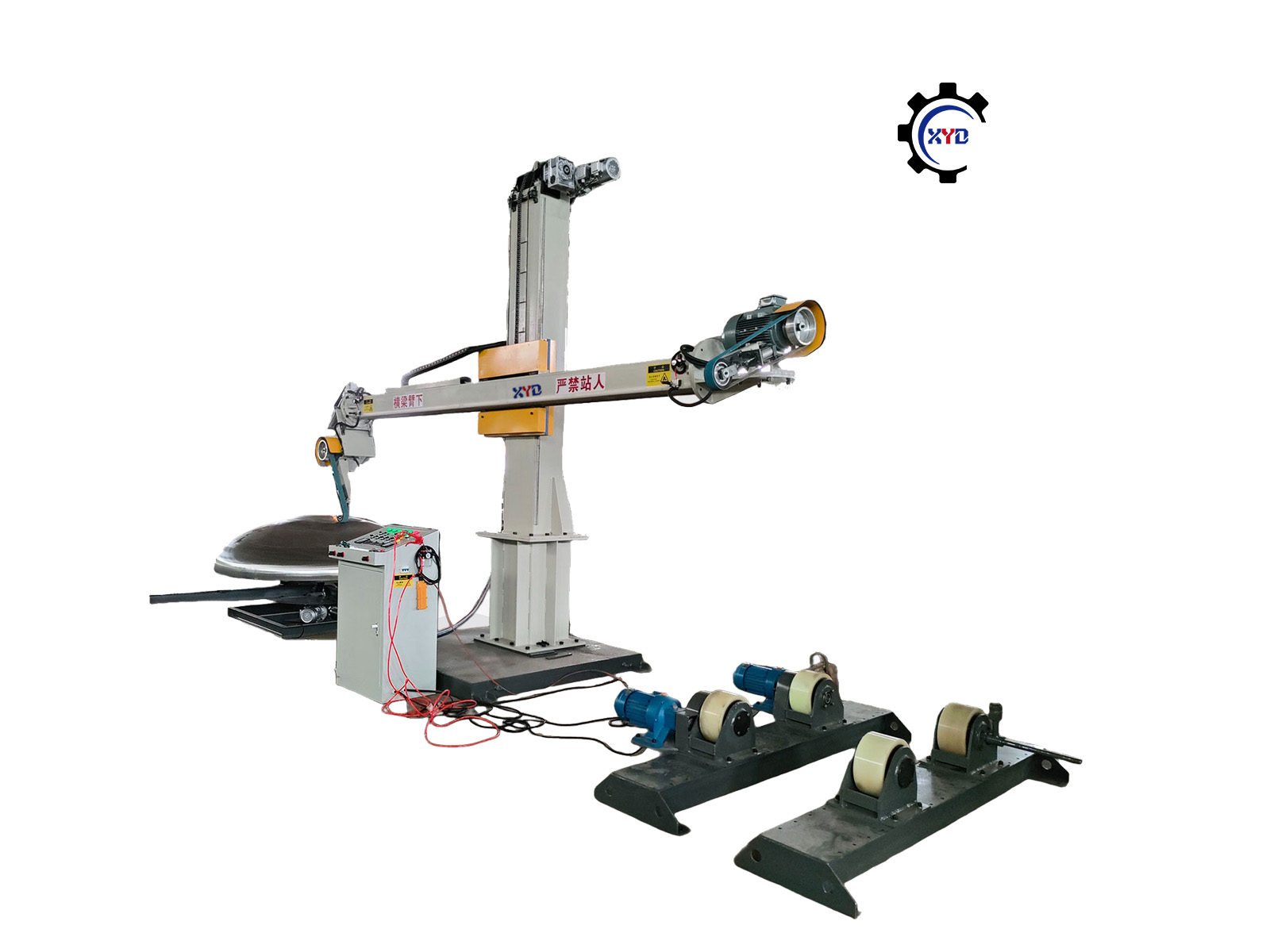

Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

Publish time:2024-03-01 11:28:23 Popularity:0 Source:未知来源

Product Name: Vertical Vessel Polishing Machine

1. Product Overview

The Vertical Vessel Polishing Machine is engineered for internal, external, and weld seam polishing of upright pressure vessels, including glass-lined reactors, enamel tanks, and stainless steel vessels. Covering φ1500–3500mm diameter and up to 4000mm in height, this machine delivers high-efficiency, high-precision polishing with advanced features such as dual-mode operation, infrared positioning, and wireless control. Ideal for applications in pharmaceutical, chemical, food, and environmental industries.

2. Key Features

| Feature | Description |

|---|---|

| Full-Coverage Polishing | Inner wall, outer wall, and weld seam polishing in one system |

| Dual Polishing Modes | Switch between circular and vertical polishing with 90° head rotation |

| Smart Monitoring System | Equipped with head-mounted monitor, infrared alignment, and wireless control |

| Dynamic Compensation Unit | 50mm motorized swing system tracks weld seams with precision |

| Enclosed Dust-Control Unit | Transparent view panel + air nozzle for real-time dust blowing |

| Operator-Friendly Design | Wireless remote + emergency stop + industrial-grade locking system |

3. Technical Specifications

| System Module | Specification |

|---|---|

| Applicable Workpiece | Glass-lined / enamel reactors & tanks (interior, exterior, weld seams) |

| Workpiece Size | Diameter: Φ1500–3500mm; Height: ≤4000mm |

| Polishing Method | Abrasive belts, flap wheels, cloth wheels (auto switch) |

| Motion Control | Inverter-driven rotation + flange-mounted swinging arm |

| Tracking Precision | ±50mm motorized weld seam adjustment |

| Observation System | Industrial monitor + infrared calibration + air nozzle blowing system |

| Operation Control | Wireless controller + real-time view + full enclosure safety |

4. Applications & Use Cases

| Industry | Typical Equipment |

|---|---|

| Pharmaceutical | Sterile mixing tanks, clean reactors, GMP vessels |

| Chemical Processing | Glass-lined reactors, anti-corrosion tanks, blending vats |

| Environmental | Clean water processing tanks, chemical storage vessels |

| Food Industry | Fermentation tanks, mixing tanks, high-finish weld seams |

Unique Advantages

-

3-in-1 polishing for inner wall, outer wall & weld seams

-

Quick-switch 90° polishing mode (circular & vertical)

-

±50mm weld seam tracking with motorized swing

-

Infrared positioning + industrial camera monitoring

-

Fully enclosed workspace + effective dust control

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service