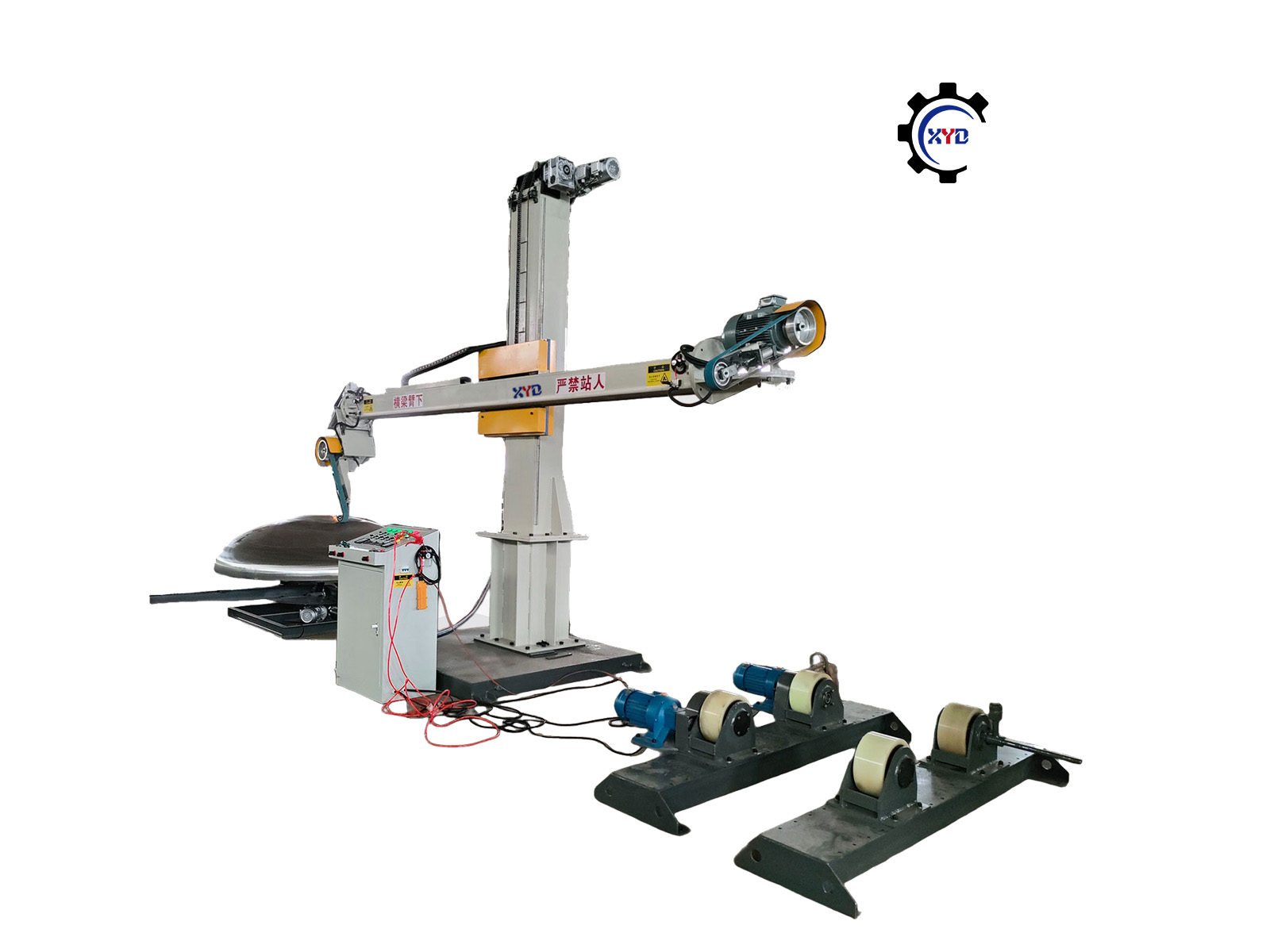

2-Axis CNC polishing machine

Publish time:2022-02-27 15:20:25 Popularity:0 Source:未知来源

1. Product Overview

The 2-Axis CNC Polishing Machine is engineered for high-efficiency surface finishing of large cylindrical metal workpieces such as stainless steel tanks and pressure vessels. Featuring a servo-controlled beam and polishing head, the machine enables precise movement and consistent results. Its adjustable-speed turntable accommodates different polishing demands, and the control system offers flexibility with Siemens CNC, Delta PLC with touchscreen, or cost-effective relay switch control. Widely used across chemical, food, pharmaceutical, and mechanical industries.

2. Key Features

| Feature | Advantage |

|---|---|

| Full CNC Automatic Polishing | Servo-driven beam and polishing head for accurate positioning and consistent performance |

| Wide Workpiece Compatibility | Supports diameters from Φ500 to Φ6000mm, lengths up to 5000mm |

| Multiple Control Options | Siemens CNC, Delta PLC + touchscreen, or standard relay control |

| High-Efficiency Grinding System | 4–7.5kW motor and 2540×50mm sanding belt for long life and reduced replacement |

| Adjustable Turntable Speed | 1–20rpm with frequency control to suit different materials and finishes |

3. Technical Specifications

1. Workpiece Capacity

| Parameter | Small Model | Large Model |

|---|---|---|

| Diameter | Φ500–3000mm | Φ3000–6000mm |

| Length | 0–3000mm | 3000–5000mm |

| Vertical Height | 3000–4000mm | 4000–5500mm |

2. Travel Configuration

| Axis | Small Model | Large Model |

|---|---|---|

| Column Travel | 0–3000mm (optional) | 0–5000mm |

| Horizontal Travel | 2500–3000mm | 3000–5000mm |

3. Power System

| Component | Specification |

|---|---|

| Polishing Motor Power | 4–7.5kW |

| Sanding Belt Size | 2540×50mm |

| Turntable Motor | 0.75–3kW |

| Turntable Speed | 1–20rpm (frequency adjustable) |

4. Polishing Efficiency

-

6–10㎡/h actual working efficiency

5. Control Options

-

Siemens CNC System: High-precision motion control

-

Delta PLC + Touchscreen: User-friendly interface

-

Standard Relay Switch Control: Cost-effective solution

4. Processing Scope & Applications

Workpiece Compatibility

-

Suitable for cylindrical components, stainless steel tanks, and pressure vessels

-

Supports polishing of both inner and outer surfaces

-

Applicable for matte, glossy, or mirror surface finishing

Industries Served

-

Stainless steel tank manufacturing

-

Chemical equipment polishing

-

Food and pharmaceutical machinery

-

Pressure vessel fabrication and welding post-treatment

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service