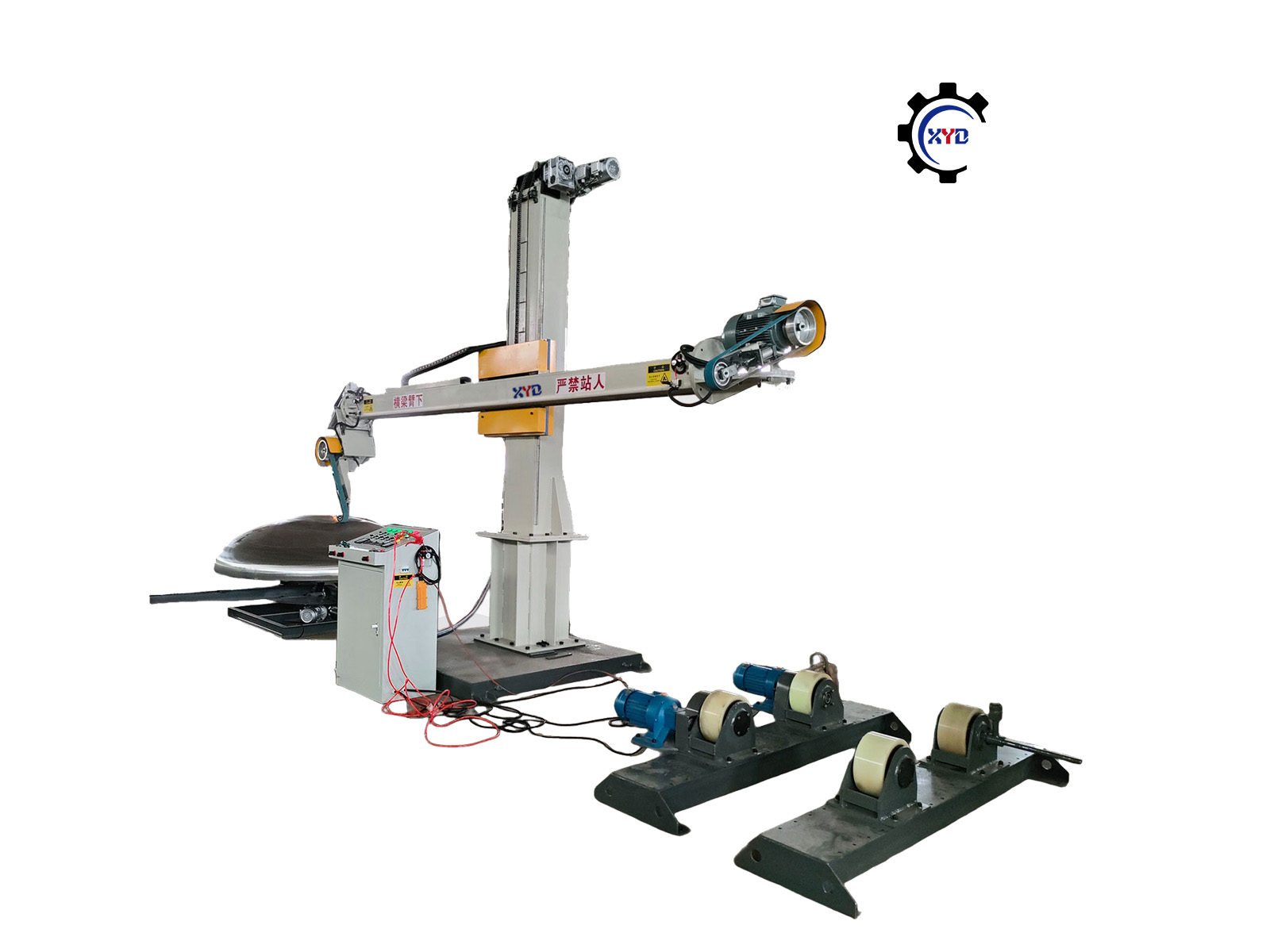

5-Axis CNC polishing machine(high precision CNC mirror polishing machine)

Publish time:2022-02-27 15:18:02 Popularity:0 Source:鑫艺达股份

1. Product Overview(DeLaval Custom Model)

The 5-Axis CNC Mirror Polishing Machine is a fully automated and precision-engineered system tailored for high-end stainless steel components. This Laval customized version features military-grade explosion-proof design, ideal for environments with flammable polishing dust. Equipped with the Siemens 828D CNC system, it achieves Ra≤0.1μm mirror finish within 18–25 minutes per workpiece, ensuring surface consistency above 98%. Designed for pharmaceutical, food-grade, and precision machinery applications that demand ultra-clean, high-gloss surfaces.

2. Key Features

| Feature | Highlights |

|---|---|

| 8K Mirror Finish | Surface roughness ≤0.1μm with uniform polishing texture |

| Explosion-Proof Design | IP65 spindle motor + 6 IP54 dustproof servo motors |

| High-Speed CNC Control | Siemens 828D system, 18–25 min/piece polishing cycle |

| Enclosed Dust Collection | Custom dust-free design for cleanroom compliance |

| Production Consistency | Batch surface quality consistency over 98% |

3. Technical Specifications

1. Machine Parameters

| Item | Specification |

|---|---|

| Dimensions | 2300×2600×2700mm |

| CNC Control | Siemens 828D |

| Drive System | 1×IP65 explosion-proof + 6×IP54 dustproof motors |

| Protection Grade | Full explosion-proof housing + motor dust covers |

2. Workpiece Performance

| Item | Details |

|---|---|

| Raw Material | Stainless Steel 2B surface (initial Ra≈0.3–0.5μm) |

| Polishing Time | 18–25 minutes per workpiece |

| Surface Finish | 8K Mirror (Ra≤0.1μm), uniform finish |

| Compatible Material | 304 / 316L Stainless Steel |

3. Process Advantages

-

Multi-axis compensation for curved surface matching

-

Adaptive pressure control ensures polishing consistency

-

Data tracking: Polishing parameters recorded per unit

-

Optional AI Vision for surface quality detection (custom)

4. Performance Comparison

| Metric | Manual Polishing | This Equipment |

|---|---|---|

| Time per Piece | 60–90 min | 18–25 min |

| Surface Roughness | Ra≈0.2–0.3μm | Ra≤0.1μm |

| Texture Uniformity | <70% | >98% |

4. Application Scope & Industries

Applicable Workpieces:

-

Stainless tank heads, shells, cones with curved surfaces

-

Mirror finish polishing for critical hygienic environments

-

Supports integration into automated production lines

Target Industries:

-

Pharmaceutical-grade stainless container production

-

Food-grade equipment polishing

-

Mirror finishing of instrument enclosures

-

Pressure vessels and special equipment manufacturing

-

Explosion-proof and dust-controlled workshops

- 2025-08-15 Dual-Head Industrial Polishing and Grinding Machine

- 2025-08-13 Dished end polishing machine -1300

- 2025-07-31 Dished end polishing machine -2000

- 2024-03-01 Reduction furnace CNC polishing machine

- 2024-03-01 Enamel reactors polishing machine (Vertical Vessel Polishing Machine)

- 2024-03-01 Tank truck CNC polishing machine

- 2024-03-01 Dished end polishing machine -3000

- 2024-03-01 Dished end polishing machine

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service