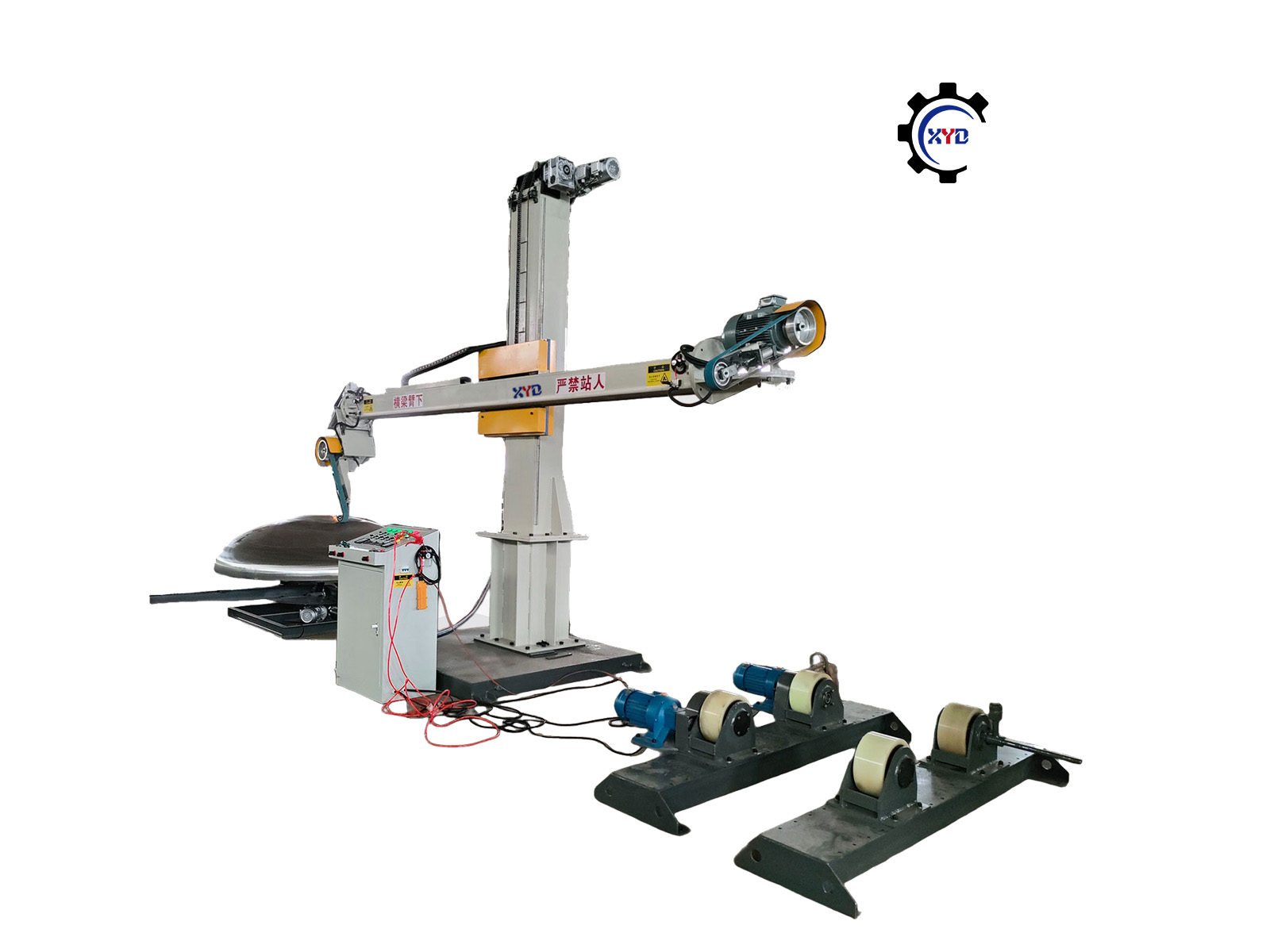

Dished head polishing machine

Publish time:2024-03-01 12:45:45 Popularity:0 Source:未知来源

1. Product Overview

The Dished End Polishing Machine is an advanced polishing solution specifically designed for the pressure vessel, chemical processing, shipbuilding, and aerospace industries. It features a reinforced base, a high-power 5.5kW polishing head, and a smart 3-axis frequency-controlled motion system. Capable of handling dish heads from φ500mm to φ3000mm, the machine delivers Ra≤0.4μm mirror-finish results using a full range of abrasive tools. With quick-change tool integration, heavy-duty rotary table, and power-optimized operation, it is a highly efficient and adaptable polishing platform.

2. Key Features

-

Heavy-Duty Workpiece Support

Standard 1-ton rotary head table, upgradable to 20 tons. Reinforced structure supports long-term continuous operation. -

Rapid Multi-Tool Switching

Supports automatic switching of abrasive belt, flap wheel, sisal wheel, and cloth wheel in under 2 minutes. Suitable for 60–800 grit polishing sequences. -

Smart Motion & Power Efficiency

Equipped with a 3-axis frequency inverter system and adaptive power management, the system saves up to 35% energy compared to conventional machines. -

Precision Polishing System

Delivers surface roughness up to Ra ≤ 0.4μm, meeting demanding polishing requirements for internal welds, outer surfaces, and complex curves. -

Comprehensive After-Sales Support

Includes free polishing process setup, 3-year warranty on core parts, 24/7 remote support, and free operator training.

3. Technical Specifications & Working Range

| Category | Specification |

|---|---|

| Working Range | φ500–3000mm head (inner and outer surfaces) |

| Power System | Total 8kW, 5.5kW 2-pole polishing motor |

| Control System | 3-axis frequency-controlled drive (beam / table / head) |

| Speed Range | Adjustable rotation speed: 1–20 rpm |

| Polishing Tools | Abrasive belt (2000×50mm), flap wheel (φ250×50mm), sisal, cloth wheel |

| Surface Finish | Ra ≤ 0.4μm; supports 60–800 grit polishing sequence |

| Efficiency | 8㎡/hour under mirror finish conditions |

| Table Load | Standard: 1 ton; Optional upgrade: up to 20 tons |

4. Application Scenarios

-

Pressure Vessel Manufacturing: Mirror polishing of nuclear-grade dish heads

-

Chemical Equipment Fabrication: Polishing of reactor head weld seams and surfaces

-

Shipbuilding Industry: Surface finishing of large stainless steel heads

-

Aerospace Manufacturing: High-precision polishing of fuel tank heads

Note: Custom non-standard configurations available upon request. Robotic arm integration and automated loading/unloading systems are also optional.

- 2025-08-14 Tank & Dished end Polishing Machine-PCL3000

- 2025-08-04 CNC Dished End Polishing Machine-3000

- 2025-08-04 CNC dished head polishing machine

- 2025-08-04 Dished head polishing machine-3500

- 2025-08-04 Tank Polishing Machine-3000

- 2025-08-01 Tank Polishing Machine-3000-1

- 2025-08-01 Tank Polishing Machine-2500-1

- 2024-03-01 Tank and Dished End Polishing Machine with 3-Axis

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service