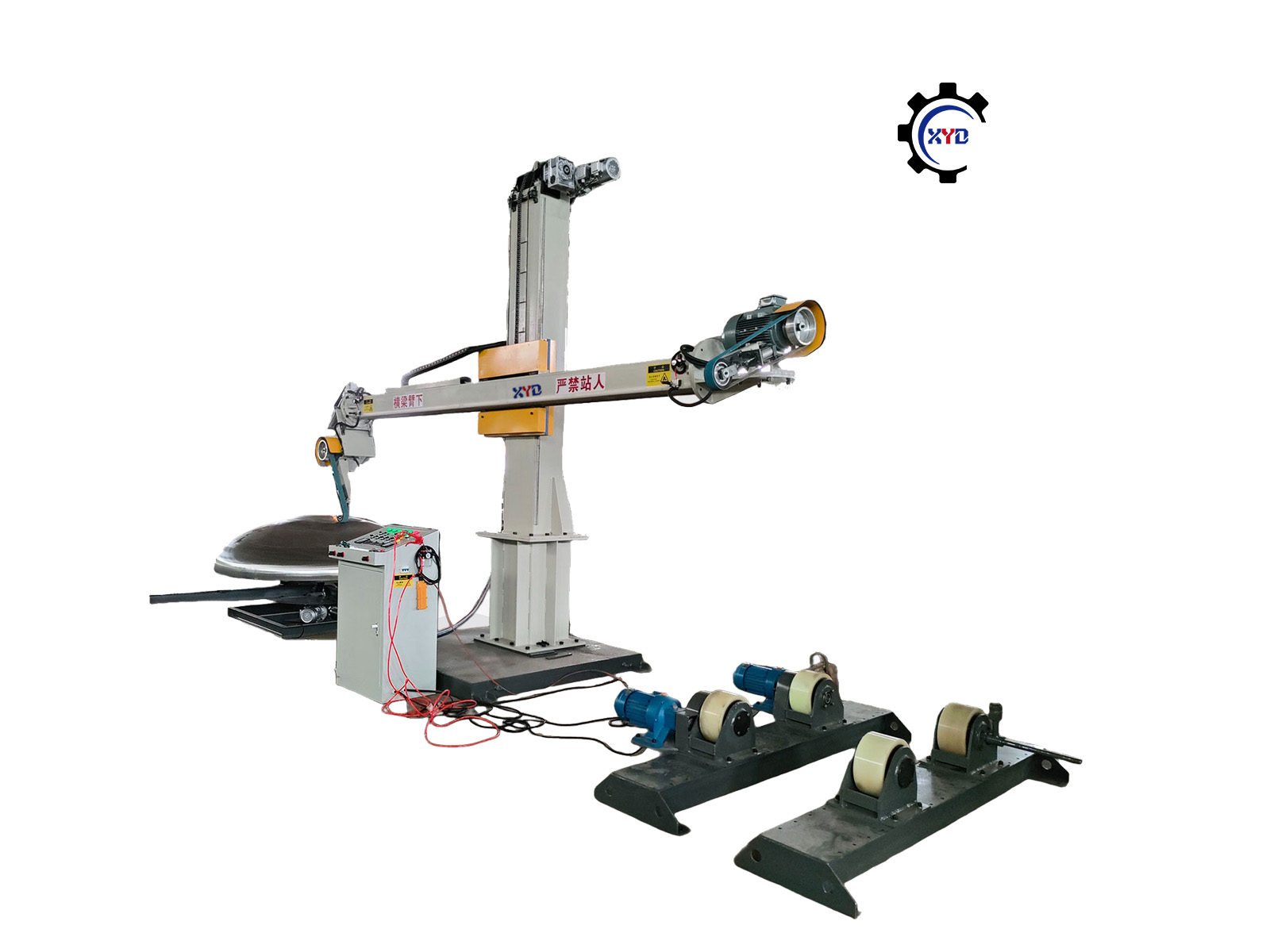

Double head tank polishing machine

Publish time:2023-06-07 06:13:13 Popularity:0 Source:未知来源

1. Product Overview

The Double-Head Tank Polishing Machine is designed for the efficient surface finishing of large-diameter tanks, with a processing range of φ500–5000mm (optional extension to 6000mm). It integrates a high-torque 5.5kW polishing head, dual-axis frequency-controlled system, and a heavy-duty rotary tank roller. Suitable for chemical containers, food-grade tanks, LNG vessels, and shipbuilding equipment, the system supports rapid tool switching and delivers mirror-grade finishes with Ra ≤ 0.4μm. Its modular design ensures low power consumption, reduced maintenance, and adaptability to various production environments.

2. Key Product Features

-

Exceptional Processing Range

Handles workpieces from φ500mm to φ5000mm, one of the widest ranges in the industry. Optional beam extension supports tanks up to 6 meters long. -

High-Torque Polishing Head

5.5kW 2-pole motor with 35N·m torque output. Maintains smooth operation even at 500rpm low-speed setting for steady grinding. -

Smart Control Architecture

Dual inverter synchronization with <0.5% speed deviation, intelligent overload protection (<0.1s response), and a user-friendly HMI interface. -

Energy-Efficient Modular Design

Operates at just 8kW total power—40% lower than industry average. Modular structure reduces maintenance time by 50%. -

Flexible Model Options

Available in Basic, Advanced, and Custom configurations, supporting automation, dust extraction, robotic integration, and ultra-heavy load upgrades.

3. Technical Specs & Polishing Matrix

▶ Technical Specifications

| Category | Specification |

|---|---|

| Working Range | φ500–5000mm (up to 6000mm optional) |

| Power System | 8kW total, 5.5kW 2-pole motor, torque: 35N·m |

| Control System | Dual-axis frequency inverter control (beam & roller) |

| Speed Range | Stepless 1–20rpm |

| Tool System | Quick switch: abrasive belt (1600×50mm), flap wheel, cloth wheel |

| Surface Finish | Ra ≤ 0.4μm; grit range 60–800 |

| Efficiency | 8㎡/hour (continuous mirror polishing) |

| Load Capacity | Standard: 2 tons; Upgradable to 20 tons |

▶ Process Capability Matrix

| Polishing Stage | Tool | Grit Range | Result Surface Roughness |

|---|---|---|---|

| Coarse Polishing | Abrasive Belt | 60–120 | Ra1.6–3.2μm |

| Semi-Finishing | Flap Wheel | 180–400 | Ra0.8–1.6μm |

| Fine Finishing | Cloth Wheel | 600–800 | Ra ≤ 0.4μm (Mirror) |

4. Verified Industrial Applications

-

Chemical Containers: 50m³ reaction tank exterior polishing

-

Food-Grade Tanks: φ4800mm stainless tank interior weld treatment

-

Marine Industry: Ballast tank and storage tank polishing

-

Energy & LNG Sector: Precision weld finishing for LNG storage tanks

ISO9001 certified system. Includes free on-site trial run, 1-year warranty for core components, lifetime tech consulting, and custom polishing kits for special materials.

- 2025-08-14 Tank & Dished end Polishing Machine-PCL3000

- 2025-08-04 CNC Dished End Polishing Machine-3000

- 2025-08-04 CNC dished head polishing machine

- 2025-08-04 Dished head polishing machine-3500

- 2025-08-04 Tank Polishing Machine-3000

- 2025-08-01 Tank Polishing Machine-3000-1

- 2025-08-01 Tank Polishing Machine-2500-1

- 2024-03-01 Tank and Dished End Polishing Machine with 3-Axis

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service