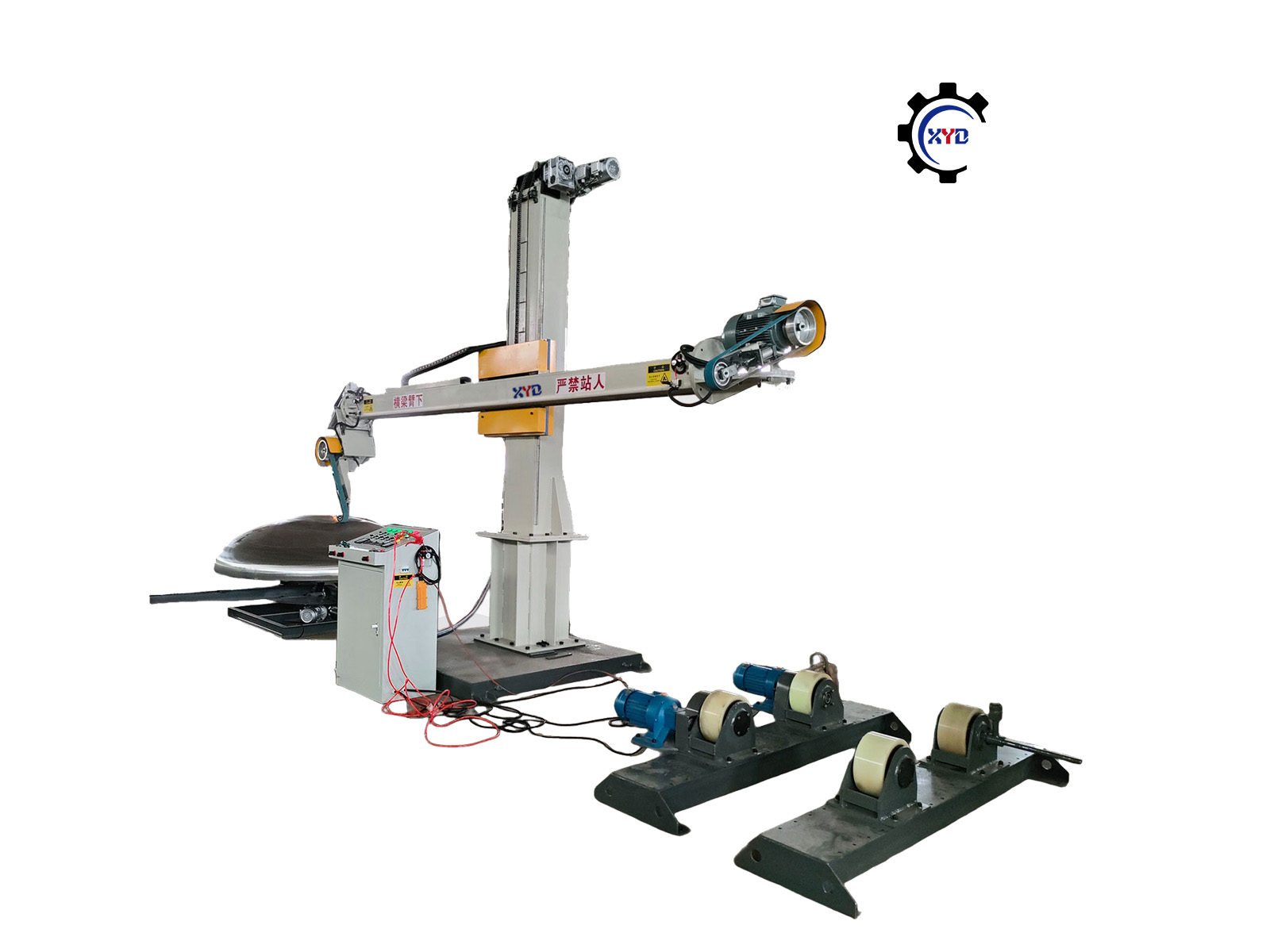

CNC dished head polishing machine

Publish time:2025-08-04 16:33:53 Popularity:0 Source:未知来源

1. Product Overview

The XYD-2 CNC Dished Head Polishing Machine, developed by XINYIDA Polishing Equipment, is specially designed for polishing stainless steel dished ends and pressure vessel heads with diameters ranging from φ400mm to 3000mm. It supports both internal and external surface polishing, delivering superior surface finishes required in food-grade, pharmaceutical, and chemical industries.

Using various grit abrasive belts and interchangeable polishing wheels, the machine achieves matte, bright, and mirror finishes with surface roughness as low as Ra<0.2μm. Its semi-automatic system enhances productivity and consistency, while an optional heavy-duty turntable allows polishing of heads weighing up to 20 tons.

2. Key Features

| Feature | Description |

|---|---|

| Multiple Finish Options | Matte, bright, and mirror surfaces with Ra ≤ 0.2μm |

| CNC Semi-Automatic System | Enhances polishing precision and surface uniformity |

| Inside & Outside Polishing | Polishes both inner and outer surfaces in one setup |

| Interchangeable System | Switch between abrasive belts and polishing wheels |

| High Productivity | Efficiency up to 10-12㎡/hour for consistent batch output |

| Branded Electrical Parts | Motor: WANNA; VFD: Zhongchen/DELTA; Circuit: Schneider |

3. Technical Specifications

| Item | Specification |

|---|---|

| Model | XYD-2-CNC-3000 |

| Working Mode | Semi-automatic |

| Beam Stroke | 3000mm (defines max polishing diameter) |

| Motor Power | 4kW or 5.5kW (Brand: WANNA) |

| Polishing Method | Belt and wheel exchangeable |

| VFD Brand | Zhongchen / DELTA |

| Circuit Brand | Schneider |

| Dish Head Diameter | 400-3000mm |

| Dish Head Height | Max 800mm |

| Dish Head Weight | Optional (Turntable load range: 1-20 tons) |

| Polishing Efficiency | 10-12㎡/hour |

| Surface Roughness | Ra ≤ 0.2μm (mirror level finish) |

4. Application Scope & Industries

Suitable Workpieces:

-

Stainless steel dished ends (elliptical, torispherical, hemispherical)

-

Pressure vessel heads

-

Tank ends and closures

-

Any metal part requiring high-surface hygiene standard

Target Industries:

-

Food-grade vessel and tank manufacturing

-

Pharmaceutical-grade equipment processing

-

Pressure vessel and chemical tank production

-

Decorative or precision metal polishing

-

OEM/ODM metal polishing service workshops

- 2025-08-14 Tank & Dished end Polishing Machine-PCL3000

- 2025-08-04 CNC Dished End Polishing Machine-3000

- 2025-08-04 CNC dished head polishing machine

- 2025-08-04 Dished head polishing machine-3500

- 2025-08-04 Tank Polishing Machine-3000

- 2025-08-01 Tank Polishing Machine-3000-1

- 2025-08-01 Tank Polishing Machine-2500-1

- 2024-03-01 Tank and Dished End Polishing Machine with 3-Axis

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service