1. Product Overview

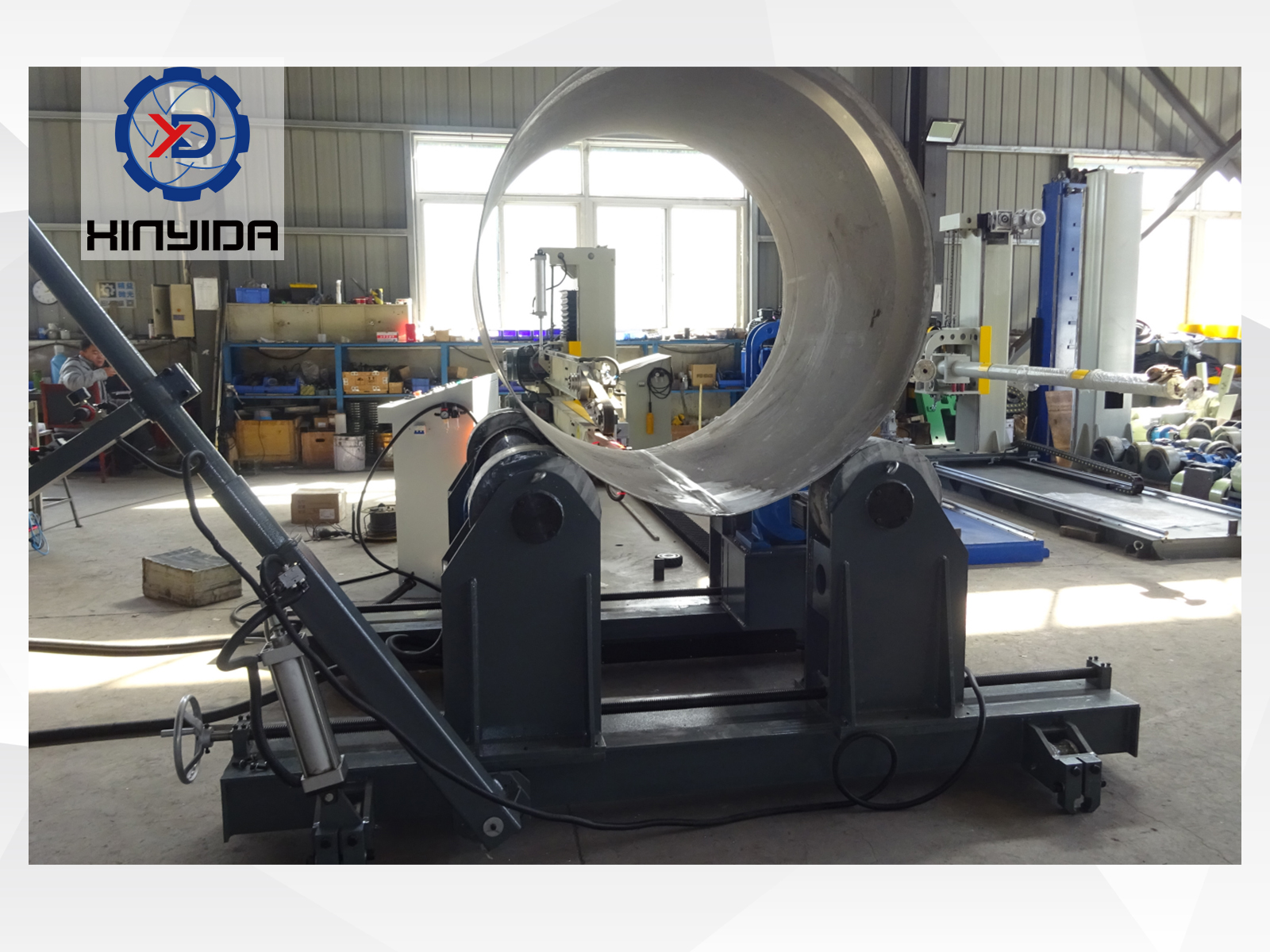

The Tank weld grinding polishing machine is specially designed for precision grinding and mirror polishing of the inner and outer walls of stainless steel cylinders, cones, and heads.

It is widely used in food, pharmaceutical, and chemical industries that require the highest standards of hygiene and surface quality for metal containers.

The machine supports interchangeable abrasive belts and polishing wheels, enabling matte, bright, and mirror finishes to meet diverse production needs. Its robust structure ensures stability, high efficiency, safety, and environmental compliance.

2. Product Features

| Feature | Function & Advantages |

|---|---|

| Multi-Function Polishing | Supports both abrasive belts and polishing wheels for versatile surface finishing. |

| High-Precision Finishing | Achieves surface roughness up to Ra ≤ 0.2 μm for premium mirror polishing. |

| Stable Structural Design | Heavy-duty frame with excellent anti-vibration performance ensures machining accuracy. |

| High-Efficiency Drive | Equipped with high-power polishing motor and frequency control for performance and stability. |

| Safe & Eco-Friendly | Fully enclosed protective cover for dust-proof operation, with optional industrial dust collector. |

3. Technical Parameters

| Item | Specification |

|---|---|

| Workpiece Types | Stainless steel cylinders, cones, heads |

| Polishing Diameter Range | 400–3000 mm (customizable) |

| Max. Processing Height | ≤ 1000 mm |

| Surface Roughness | Ra ≤ 0.2 μm |

| Polishing Method | Interchangeable abrasive belt / polishing wheel |

| Motor Power | 4 kW / 5.5 kW (optional) |

| Control Mode | CNC / PLC automatic control |

| Optional Features | Industrial dust collection system, water cooling system |

4. Processing Scope & Applications

Processing Scope

-

Inner and outer head polishing

-

External finishing of cylinders and conical vessels

-

Matte, bright, and mirror surface treatments

Application Industries

-

Food-grade stainless steel container manufacturing

-

Pharmaceutical equipment and process tanks

-

Chemical reactors and storage tanks

-

High-cleanliness metal container polishing

QQ Customer Service

QQ Customer Service