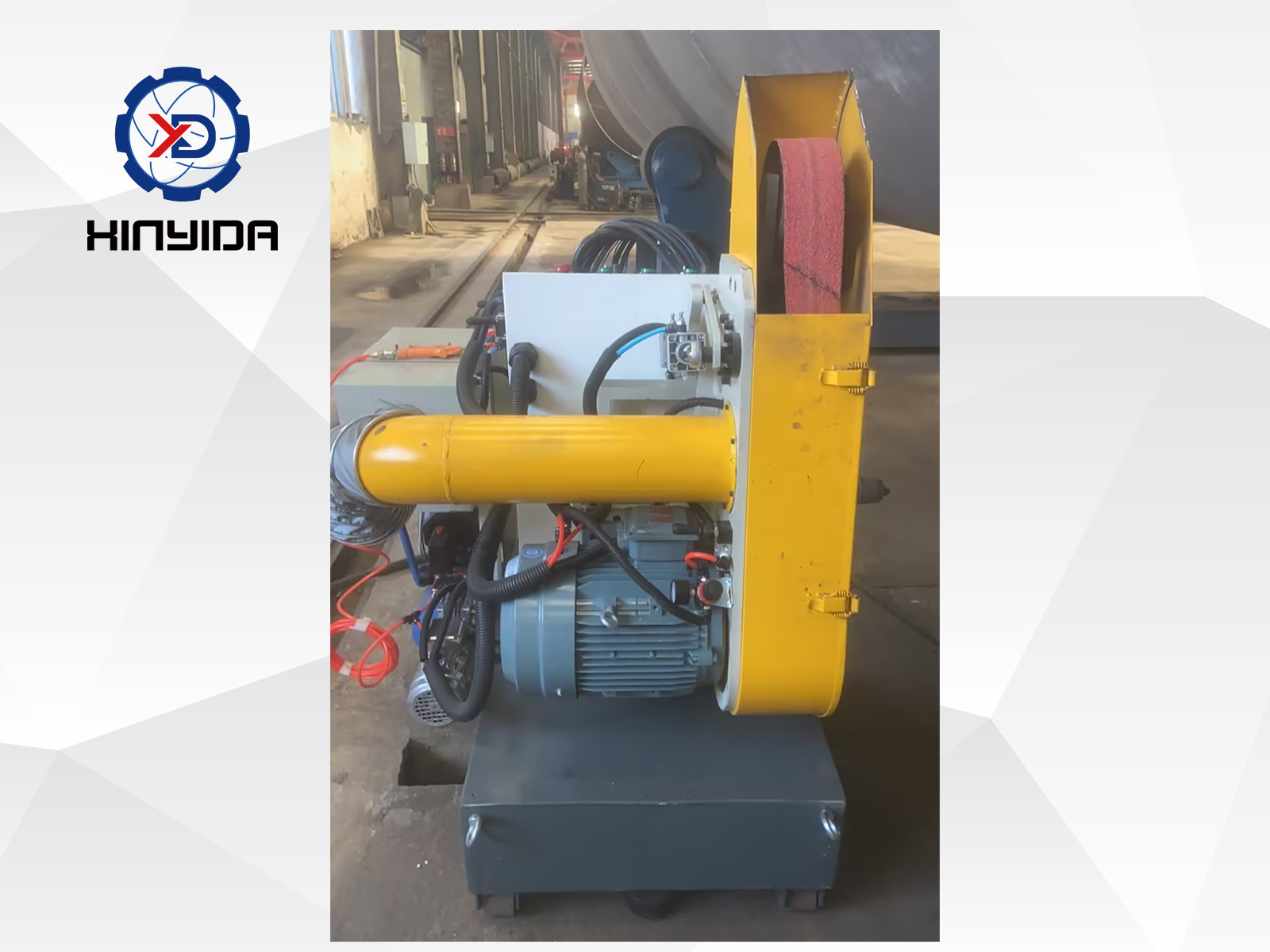

Weld Seam Grinding Trolley

This Portable Welding Seam Grinding Trolley is designed for circular seam grinding and polishing on cylindrical metal tanks such as stainless steel storage tanks, pressure vessels, and similar components. It can also be used for pre-weld V-groove slag removal and oxide cleaning.

Weld Seam Grinding Trolley XYD-HF

- Introduction

- Video

1. Product Description

This Portable Welding Seam Grinding Trolley is designed for circular seam grinding and polishing on cylindrical metal tanks such as stainless steel storage tanks, pressure vessels, and similar components. It can also be used for pre-weld V-groove slag removal and oxide cleaning.

The unit adopts a compact wheeled chassis, allowing easy maneuverability on-site. It integrates a belt grinding system and cutting disc module, with automated lateral tracking, ensuring efficient and consistent grinding along circumferential weld seams. The system includes a dust suction pipeline, spark filter box, and silent air pump, working in conjunction with an industrial-grade dust collector for a clean and safe working environment.

2. System Components

-

Mobile trolley chassis with wheel group

-

Belt grinding module + cutting disc head

-

Weld seam locking & centering system

-

Left-right automatic travel mechanism

-

Dust extraction system with spark filter

-

Silent air pump and dual-inverter control cabinet

-

Industrial dust collector (included)

3. Technical Specifications

| Item | Specification |

|---|---|

| Machine Dimensions | 1100mm × 900mm × 1500mm |

| Applicable Tank Diameter | φ1500mm – φ4500mm |

| Grinding Method | Belt grinding + cutting disc rough grind |

| Sand Belt Size | 2000mm × 80mm |

| Grinding Speed | 0.8 – 1 m/min (based on roller speed) |

| Electrical System | Dual inverters + control cabinet |

| Total Power | 11KW (including dust collector) |

| Total Weight | Approx. 500KG |

4. Key Advantages

-

Versatile Application: Suitable for a wide range of tank diameters (φ1.5m to 4.5m)

-

Mobile and Flexible: Quick setup and operation in various environments

-

Automated Grinding: Seam-following function ensures uniform polishing

-

Dual Grinding System: Combines coarse and fine processes

-

Eco-friendly Design: Integrated spark filtering and dust extraction

-

Easy Operation: Manual pushing + automatic grinding workflow

5. Application Industries

-

Stainless steel tank manufacturing

-

Pressure vessel post-weld surface treatment

-

Food, chemical, and pharmaceutical equipment polishing

-

Pre-welding surface cleaning

-

Cylindrical weld seam processing in workshop or field

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service