Barrel Polishing Machine Technical Analysis and Application Guide

Publish time:2024-03-21 01:39:42 Popularity:0 Source:未知来源

Technical analysis and application guide of barrel polishing machine

I. Core product features

High-efficiency polishing system:

Dual-mode polishing: cloth grinding wheel (rough polishing) + flap wheel (fine polishing)

Mirror polishing ability: Ra≤0.28μm (in line with ISO 1302 standard)

Continuously variable speed control: 1500-3000rpm (±1% speed accuracy)

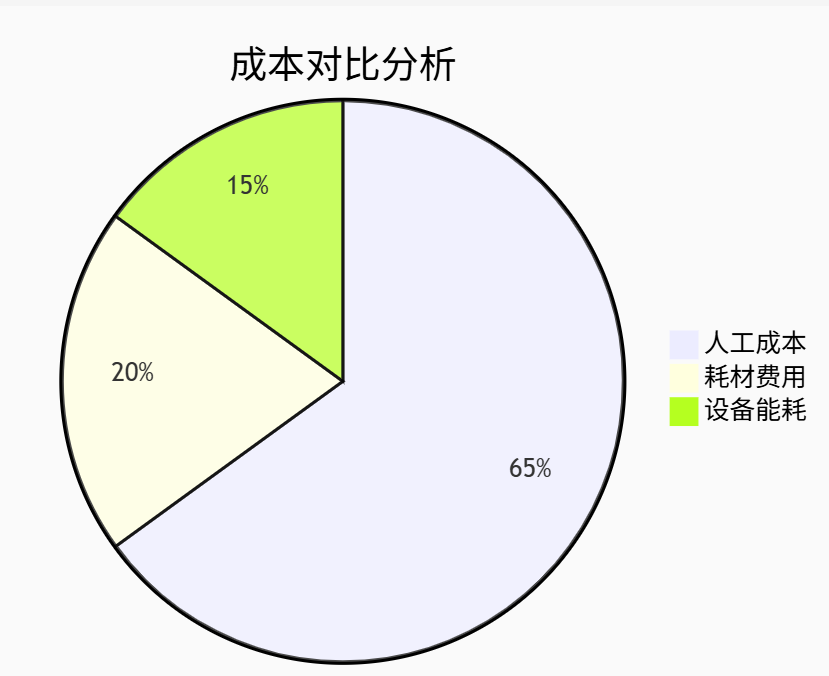

Economic indicators:

II. Detailed Technical Parameters

| Item | Specifications | Testing Standards |

|---|---|---|

| Polishing Efficiency | 8–10 m²/h (single pass) | GB/T 38276-2019 |

| Surface Roughness | 0.28–1.6 μm (adjustable) | ISO 4287 |

| Motor Power | 5.5–11 kW (variable frequency control) | IEC 60034 |

| Applicable Drum Diameter | Φ600–Φ3000 mm (customizable) | Custom design |

III. Safety Protection System

-

Triple Protection Design

-

Mechanical Protection: Interlocking door (EN ISO 14119)

-

Electrical Protection: IP54 rating (IEC 60529)

-

Health Protection: Integrated dust removal system (airflow ≥3000 m³/h)

-

-

Ergonomic Improvements

-

Remote control system (operating distance ≥5 m)

-

Complies with OSHA noise standards (≤82 dB(A))

-

IV. Intelligent Control System

-

Process Parameter Memory

# Typical parameter storage logic class PolishingRecipe: def __init__(self, material): self.speed = {'stainless':2500, 'carbon_steel':1800} self.pressure = {'rough':0.3, 'fine':0.1}

-

Fault Diagnosis System

-

Vibration monitoring (ISO 10816 standard)

-

Temperature protection (PT100 sensor)

-

V. Industry Application Comparison

| Industry | Configuration Solution | Efficiency Improvement |

|---|---|---|

| Chemical Containers | Explosion-proof + acid washing function | Reduces project time by 40% |

| Food Equipment | 316L stainless steel contact parts | Meets FDA hygiene standards |

| Energy Pipelines | High-power deep weld polishing | Rework rate ↓80% |

VI. Maintenance Guidelines

-

Daily Inspection Checklist

-

Polishing disc wear (<5 mm thickness)

-

Belt tension (10–15 mm deflection)

-

Air pressure system (0.6±0.05 MPa)

-

-

Key Component Lifespan

Component Replacement Cycle Warning Method Carbon Brushes 500 h Current fluctuation monitoring Bearings 3000 h Vibration analysis Filters 200 h Pressure difference alarm

Innovative Features

-

Optional AR-assisted operation (real-time polishing path display)

-

Cloud data management (records polishing parameters & quality data)

Note: Actual parameters should be adjusted based on workpiece material (e.g., stainless steel SUS304 / carbon steel Q235) and process requirements. Process validation is recommended before first use.

This equipment is CE-certified and complies with GB 5226.1 machinery electrical safety standards, suitable for surface treatment in industries such as pressure vessels, shipbuilding, and chemical equipment. For customized solutions, workpiece samples can be provided for trial polishing.

- 2025-12-23 What are the types of polishing

- 2025-12-23 What is the working principle of a flat plate polishing machine

- 2025-11-14 Precautions to Take Before and After Operating a Polishing Machine

- 2025-11-04 Have you maintained the polishing machine?

- 2025-10-14 The difference between single-station pipe polishing machines and multi-station pipe polishing machines

- 2025-10-08 Why the Semiconductor Industry Cannot Do Without Automatic Polishing Equipment?

- 2025-09-25 Why Do Pressure Vessels Need Polishing?

- 2025-09-24 What are the types of circular tube polishing machines

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service