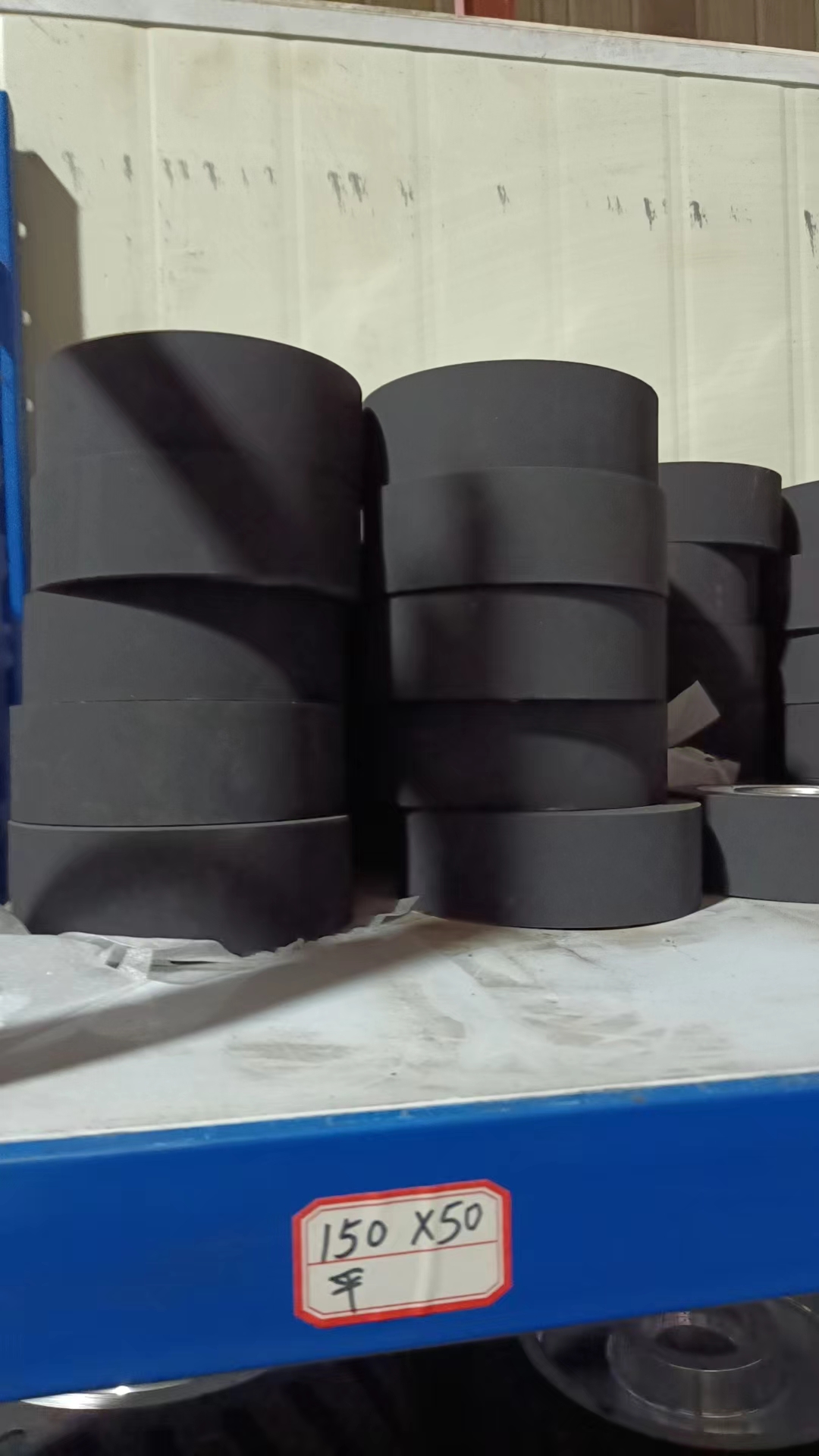

Rubber Contact Wheel for Belt Polishing Machine

The rubber contact wheel is the key component where the abrasive belt contacts the workpiece in a belt polishing machine.

Wear-resistant Rubber Roller Assembly

- Introduction

1. Product Introduction

The rubber contact wheel is the key component where the abrasive belt contacts the workpiece in a belt polishing machine. Mounted on the spindle, it supports the belt and provides stable contact pressure during operation. With excellent elasticity, it absorbs vibration and distributes polishing pressure evenly, resulting in a smooth and consistent surface finish. It is widely used in stainless steel, aluminum, automotive, and hardware surface finishing industries.

2. Structure Classification

| Category | Type | Features & Applications |

|---|---|---|

| By Structure | Solid Rubber Wheel | Entirely rubber-built, high rigidity and wear resistance, ideal for coarse polishing or deburring. |

| Rubber-Coated Wheel | Aluminum or steel core coated with rubber, suitable for medium and fine polishing, well balanced. | |

| Interchangeable Ring Wheel | Replaceable rubber ring, easy maintenance, cost-saving. | |

| By Hardness | Soft Wheel (30–50A) | Highly elastic, ideal for curved or precision finishing. |

| Medium-Hard Wheel (60–70A) | Versatile and widely applicable. | |

| Hard Wheel (80–90A) | Strong support, suitable for heavy grinding or material removal. | |

| By Function | Main Contact Wheel | Directly contacts the belt to apply polishing pressure. |

| Idler / Tension Wheel | Guides or tensions the belt, not involved in grinding. | |

| Wheel Assembly | Includes bearings and hub for easy installation or replacement. |

3. Technical Specifications

| Item | Range / Description |

|---|---|

| Outer Diameter | 150–500 mm |

| Width | 30–150 mm |

| Hardness | 30A–90A (Shore) |

| Material | NBR, EPDM, PU, or customized compounds |

| Balance Grade | G6.3 or higher |

| Mounting Type | Keyway / Threaded Shaft / Flange Mount |

4. Key Features

-

Excellent elasticity to adapt to surface irregularities.

-

Vibration damping and noise reduction for stable operation.

-

Wear-resistant rubber coating ensures long service life.

-

Superior dynamic balance for accurate and smooth polishing.

5. Application Fields

| Industry | Description |

|---|---|

| Stainless Steel Fabrication | Surface polishing of pipes, tank heads, and vessels |

| Automotive Manufacturing | Polishing of wheel rims, exhaust pipes, and trim parts |

| Hardware Products | Finishing of faucets, handrails, and handles |

| Aerospace & Medical | Precision part grinding and mirror finishing |

Customized Rubber Contact Wheels (35°–95°) with Aluminum Core / Toothed Surface | Bearing-Mountable | Xinyida Factory Supply

Contact information

QR code

QQ Customer Service

QQ Customer Service