Multi-functional Automatic Polishing System: Precision Machining Solution for Cross-Material Multi-Process Applications

Publish time:2022-11-07 19:24:05 Popularity:0 Source:未知来源

Anhui Xinyida's new generation intelligent polishing equipment integrates high-efficiency processing with intelligent control, providing comprehensive surface treatment solutions for various metals and hard plastic workpieces. This system combines advanced mechanical design with smart control technology, revolutionizing traditional polishing operations.

I. Full Material-Compatible Polishing System

1. Multi-Material Processing Capabilities

-

Metal Material Processing

-

Light metals: Aluminum/Magnesium alloys (surface roughness up to Ra0.1μm)

-

Ferrous metals: Stainless steel/Carbon steel (rust removal efficiency improved by 300%)

-

Special alloys: Titanium/Nickel-based alloys (custom polishing solutions)

-

-

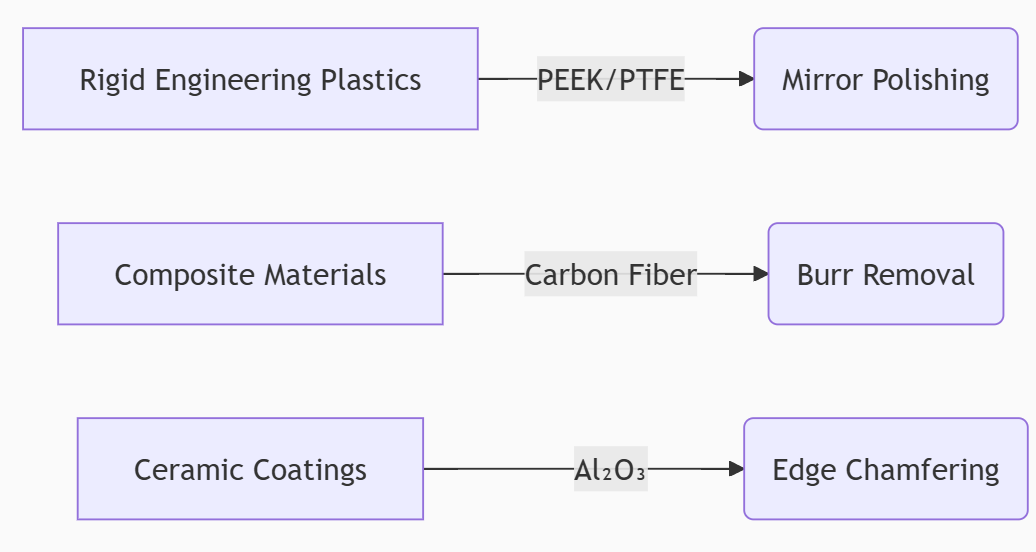

Non-Metal Material Processing

2. Integrated Multi-Process Modules

-

Five-in-One Processing System

Process Module Technical Parameters Processing Effect Deburring 60-120 grit sanding belt R angle ≤0.1mm Precision Chamfering 45° adjustable tool head Consistency ±0.05mm Multi-stage Polishing Combination of flap wheel + cloth wheel Adjustable Ra0.02-1.6μm Ultrasonic Cleaning 40kHz frequency Cleanliness ≤5mg/m² Rust Prevention Nano-coating device Salt spray test ≥96h

II. Intelligent Control System

1. Full Parameter Visual Monitoring

-

Digital Control Panel

[Real-time Monitoring] - Voltage fluctuation: ±5% auto-compensation - Current load: Automatic shutdown when overloaded - Frequency adjustment: 50-200Hz stepless speed regulation - Time control: 0.1-999 minutes preset [Alarm Functions] 1. Sanding belt wear warning 2. Overload protection alert 3. Process completion reminde

2. Automated Processing Workflow

-

Unattended Operation Mode

-

Automatic workpiece recognition (laser diameter measurement)

-

Automatic process parameter matching (cloud database)

-

Adaptive feeding system (pressure feedback control)

-

Automatic unloading (robot interface)

-

III. Special Structure Processing Solutions

1. Complex Surface Treatment Technology

-

Special Fixtures for Irregular Parts

-

Tubular parts: Self-centering flexible fixture (adapts to Φ3-150mm)

-

Hole structures: Universal polishing head extension system (depth ≤500mm)

-

Narrow gap processing: Micro sanding belt unit (minimum 3mm clearance)

-

-

Dead Angle Elimination Solutions

• Multi-axis linkage system: 6-DOF robotic arm • Internal cavity polishing: Flexible shaft design • Edge processing: Magnetic polishing media

IV. Eco-Friendly High-Efficiency Production System

1. Dust Removal and Purification Configuration

-

Modular Dust Removal Solution

Pollution Type Treatment Device Emission Standard Metal dust Cyclone + HEPA filtration ≤1mg/m³ Polishing exhaust Activated carbon adsorption GB16297-1996 Noise pollution Soundproof enclosure design ≤75dB(A)

2. Multi-Process Grinding and Polishing System

-

Sanding Belt Grinding Unit

-

Efficiency comparison: 5-8 times faster than traditional methods

-

Sanding belt lifespan: Average 200-300 hours

-

Replacement time: ≤3 minutes quick change

-

-

Precision Polishing Unit

1. Rough polishing: Flap wheel (#80-#120) 2. Semi-finishing: Nylon wheel (#150-#240) 3. Fine polishing: Cloth wheel (#400-#600) 4. Mirror polishing: Wool wheel + diamond paste (Ra≤0.01μm)

This system supports customization and can be configured as either single workstations or automated production lines according to output requirements. CE-certified equipment comes with remote diagnostic services to maximize production efficiency. Anhui Xinyida's professional team provides comprehensive support including process development and sample processing, helping customers upgrade their surface treatment technologies.

- 2025-12-23 What are the types of polishing

- 2025-12-23 What is the working principle of a flat plate polishing machine

- 2025-11-14 Precautions to Take Before and After Operating a Polishing Machine

- 2025-11-04 Have you maintained the polishing machine?

- 2025-10-14 The difference between single-station pipe polishing machines and multi-station pipe polishing machines

- 2025-10-08 Why the Semiconductor Industry Cannot Do Without Automatic Polishing Equipment?

- 2025-09-25 Why Do Pressure Vessels Need Polishing?

- 2025-09-24 What are the types of circular tube polishing machines

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service