Polishing Machines, Grinding Machines, and Sanding Machines: Core Differences and Selection Guide for Surface Treatment Equipment

Publish time:2022-12-26 19:50:17 Popularity:0 Source:未知来源

In the field of metal processing and surface treatment, polishing machines, grinding machines, and sanding machines are the three most commonly used pieces of equipment. However, many users still struggle to differentiate between them when making selections. This article provides an in-depth analysis of their core differences to help you accurately match your production needs.

1. Key Comparison Table

| Equipment Type | Core Function | Processing Precision | Typical Applications | Surface Effect |

|---|---|---|---|---|

| Polishing Machine | Achieves mirror-like finish | Ra ≤ 0.1 μm | High-end hardware/bathroom fixtures/precision parts | Mirror/matte/brushed finish |

| Grinding Machine | Removes burrs/chamfers/primary polishing | Ra 0.8-1.6 μm | Beads/die-cast parts/standard parts | Uniform matte finish |

| Sanding Machine | Levels surfaces/removes rust/coatings | Ra 3.2-6.3 μm | Sheet metal/woodworking/ship repair | Rough texture |

2. In-Depth Analysis of Equipment Characteristics

-

Polishing Machine (Precision Grade)

-

Process Features:

-

Progressive polishing: Rough → Medium → Fine

-

Compatible with 8 types of polishing wheels (wool/silicon carbide/diamond, etc.)

-

-

Technological Breakthroughs:

-

Latest magnetorheological polishing achieves nanometer-level precision

-

Intelligent pressure control system (±0.05 MPa error)

-

-

-

Grinding Machine (Efficiency Type)

-

Innovative Design:

-

3D vibration polishing (amplitude adjustable 0.5-5 mm)

-

Eco-friendly water grinding technology (saves 30% water)

-

-

Typical Configurations:

-

Ceramic/high-frequency steel abrasives optional

-

Automatic sorting system (±0.2 mm precision)

-

-

-

Sanding Machine (Multi-functional Type)

-

Technical Parameters:

-

Pneumatic type: 0.6-0.8 MPa working pressure

-

Electric type: 1000-3000 W power optional

-

-

Safety Upgrades:

-

Double insulation protection (IP54 compliant)

-

Dust-proof motor design (3x longer lifespan)

-

-

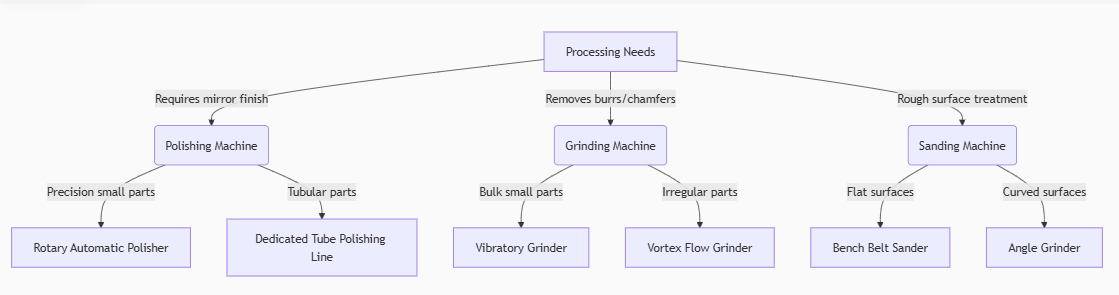

3. Selection Decision Tree

4. Industry Application Gold Standards

-

Automotive Components

-

Sanding (removes weld slag) → Grinding (deburring) → Polishing (pre-plating treatment)

-

Reduces processing time by 40%

-

-

Jewelry Manufacturing

-

Grinding (rough shaping) → Polishing (mirror finish)

-

Improves surface gloss by 300%

-

-

Aerospace Parts

-

CNC sanding (contour trimming) → Electro-polishing (stress relief)

-

Increases fatigue life by 2.5x

-

5. Key Maintenance Points

-

Polishing Machine

-

Daily: Clean polishing wax residue

-

Monthly: Calibrate spindle dynamic balance

-

-

Grinding Machine

-

Weekly: Screen worn abrasives

-

Quarterly: Replace damping springs

-

-

Sanding Machine

-

Per use: Check carbon brush wear

-

Annually: Lubricate bearings

-

6. 2023 Technology Trends

-

Smart Manufacturing

-

AI vision inspection (automatically detects surface defects)

-

IoT remote monitoring (98% fault prediction accuracy)

-

-

Green Production

-

Dry polishing (95% dust recovery)

-

Low-temperature grinding (25% energy reduction)

-

Expert Advice: We recommend testing samples first for process validation. Our engineers will customize:

-

Equipment selection plans

-

Consumable matching solutions

-

Cost-benefit analysis

📞 Get your tailored solution now: 0551-65571688

(100+ success cases across 8 industries available for reference)

Note: Data based on ISO 8501-1 surface treatment standards. Actual results may vary slightly due to material properties. Regular equipment calibration is recommended to ensure quality.

- 2025-12-23 What are the types of polishing

- 2025-12-23 What is the working principle of a flat plate polishing machine

- 2025-11-14 Precautions to Take Before and After Operating a Polishing Machine

- 2025-11-04 Have you maintained the polishing machine?

- 2025-10-14 The difference between single-station pipe polishing machines and multi-station pipe polishing machines

- 2025-10-08 Why the Semiconductor Industry Cannot Do Without Automatic Polishing Equipment?

- 2025-09-25 Why Do Pressure Vessels Need Polishing?

- 2025-09-24 What are the types of circular tube polishing machines

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service