2024

Publish time:2025-06-28 00:55:45 Popularity:0 Source:未知来源

1. Product Overview

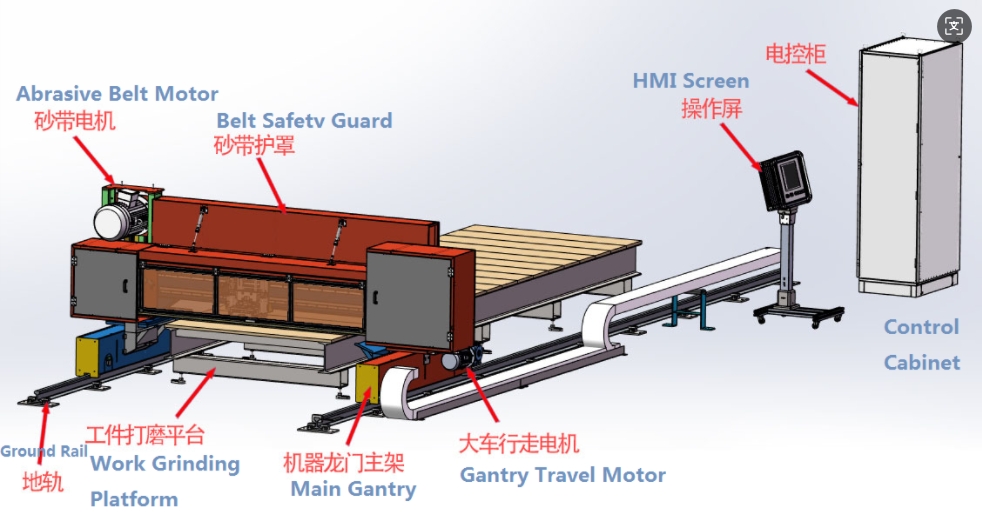

This Flat Sheet Brushing Machine is specially designed for surface grinding and brushing of flat metal plates such as stainless steel, aluminum, and carbon steel. It uses abrasive belt grinding as the primary method and incorporates a PLC servo control system to set plate width, length, and grinding position, ensuring automatic and consistent surface treatment.

It is widely used in metal decoration, kitchenware, elevators, doors, and transportation components.

2. Key Features

-

Variable Frequency Grinding Head

Adjustable speed for high grinding efficiency. -

PLC + Servo Control System

Automatically controls grinding area for high precision. -

Multiple Grit Capability (80–400 grit)

Gradual polishing for consistent brushed or matte finish. -

Pneumatic Floating Grinding Head

Ensures close contact with uneven plates; suitable for continuous operation. -

Customizable Dimensions

Processing range can be tailored to user’s sheet sizes.

3. Technical Specifications

| Category | Specification |

|---|---|

| Total Power | Approx. 19 kW |

| Machine Weight | Approx. 1.7 Tons |

| Machine Dimensions | 3665 × 1810 × 1523 mm |

| Max Workpiece Size | Width ≤1500mm, Length ≤6000mm, Thickness 3–10mm |

| Polishing Speed | 240 mm/min |

| Head Travel Speed | 0–28 m/min |

| Carriage Travel Speed | 0–6 m/min (VFD controlled) |

| Grinding Head Control | Pneumatic floating + Abrasive belt |

| Belt Size | 160 × 8000 mm |

| Surface Roughness | Ra ≤ 0.6μm |

| Productivity | Approx. 8㎡/hour |

4. Applications

-

Stainless steel decorative sheet finishing

-

Elevator panel brushing

-

Metal kitchenware and furniture surface treatment

-

Metal doors, railings, and façade finishing

-

Batch sheet polishing in sheet metal fabrication

Online Message

Contact information

QR code

QQ Customer Service

QQ Customer Service