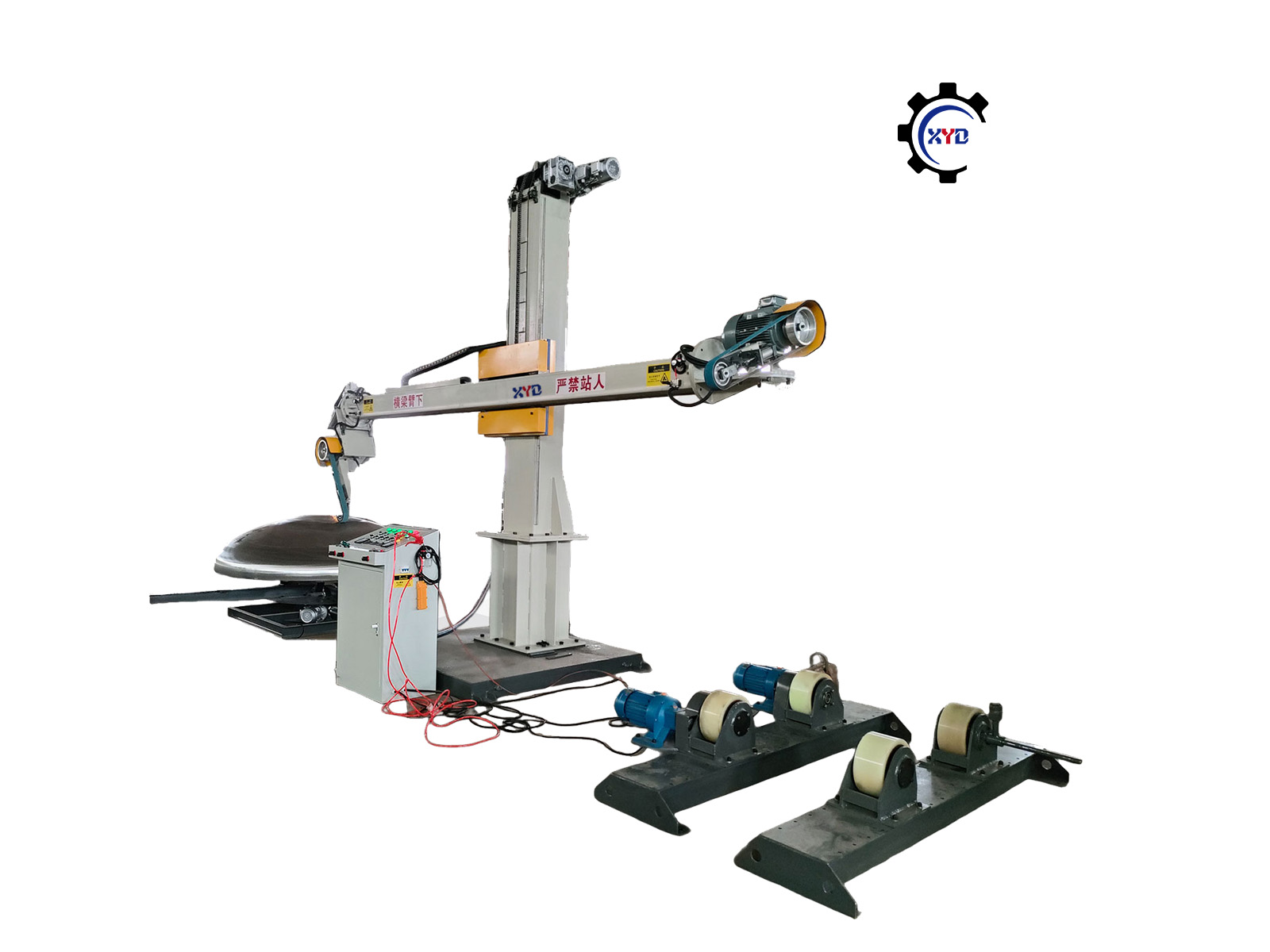

Tank and Dished End Polishing Machine with 3-Axis

The equipment consists of beam, column, base, can body grinding head, head grinding head, can body rolling table, head rolling table, control cabinet and so on. Suitable for internal and external polishing of can body φ800mm-3000mm, head φ500mm-3000mm, optional head rotary table loading range: 1-20 tons.

Tank and Dished End Polishing Machine with 3-Axis XYD-CZJ

- Introduction

- Video

1. Product Overview

The Tank & Dished end Polishing Machine is a high-precision, intelligent polishing system designed for industries such as pressure vessel manufacturing, chemical equipment, food machinery, and new energy. Featuring dual independent polishing heads and twin rotary platforms, the machine allows for efficient one-stop polishing of cylindrical tanks and dish ends. With intelligent control, quick tool switching, and three-axis motion coordination, it supports full-process polishing from rough sanding to mirror finishing.

2. Key Features

-

Dual-Station Integration

Simultaneous polishing for tank and head sections, minimizing transition time. -

Quick-Change Multi-Tool System

Supports fast switching of abrasive belt, flap wheel, sisal wheel, and cloth wheel in <3 minutes. Covers full polishing range from 60 to 800 grit. -

Smart Motion Control

Three-axis frequency-controlled system (beam, rotary table, polishing head) with PID regulation ensures constant linear speed and uniform finish. -

Heavy-Duty Capability

Standard 1-ton rotary table, customizable up to 20 tons. Designed for large workpieces such as stainless steel pressure vessels. -

Eco & Low-Noise Design

Integrated dust collection ports for external vacuum system, noise level maintained <75dB.

3. Technical Specifications & Working Range

| Category | Specifications |

|---|---|

| Working Range | Tank Diameter: φ800–3000mm; Head Diameter: φ500–3000mm |

| Power System | Total: 12kW; Dual 4kW motors (2-pole & 4-pole) |

| Control System | 3-axis frequency drive (beam lift, rotation, polishing head) |

| Speed Range | 0.5–20 rpm (adjustable) |

| Polishing Tools | Abrasive belt (2000×50mm), flap wheel (φ250×50mm), sisal, cloth wheel |

| Surface Finish | Ra ≤ 0.4μm; Grit range 60–800 |

| Efficiency | Up to 8㎡/hour (mirror finish conditions) |

| Load Capacity | Standard: 1 ton; Optional upgrade: up to 20 tons |

4. Application Areas

-

Pressure Vessel Manufacturing: Inner polishing of dish heads, outer finishing of tanks

-

Chemical Equipment Fabrication: Polishing of large reaction vessels and weld seams

-

Food Machinery Production: Seam grinding and finishing for stainless steel tanks

-

New Energy Equipment: Surface treatment of battery housings and cylindrical parts

Optional: Robotic arm for automated loading/unloading (requires 2.5m extra space); Standard electrical components are 3C certified for industrial-grade safety.

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service