Pipe polishing machine

The Automatic pipe polishing machine is designed for precision exterior surface grinding and linishing of steel welded pipes, seamless pipes, and round solid rods. It can also process hydraulic cylinder exteriors and other cylindrical products, delivering a high-quality polished finish. Equipped with double variable frequency grinding motors (7.5KW each), the TCM-WP supports both grinding wheels and abrasive sanding belts. Its versatility makes it widely applicable in industries such as pharmaceutical, medical, food processing, water purification, pressure vessels, cosmetics, wastewater treatment, semiconductors, and photovoltaics.

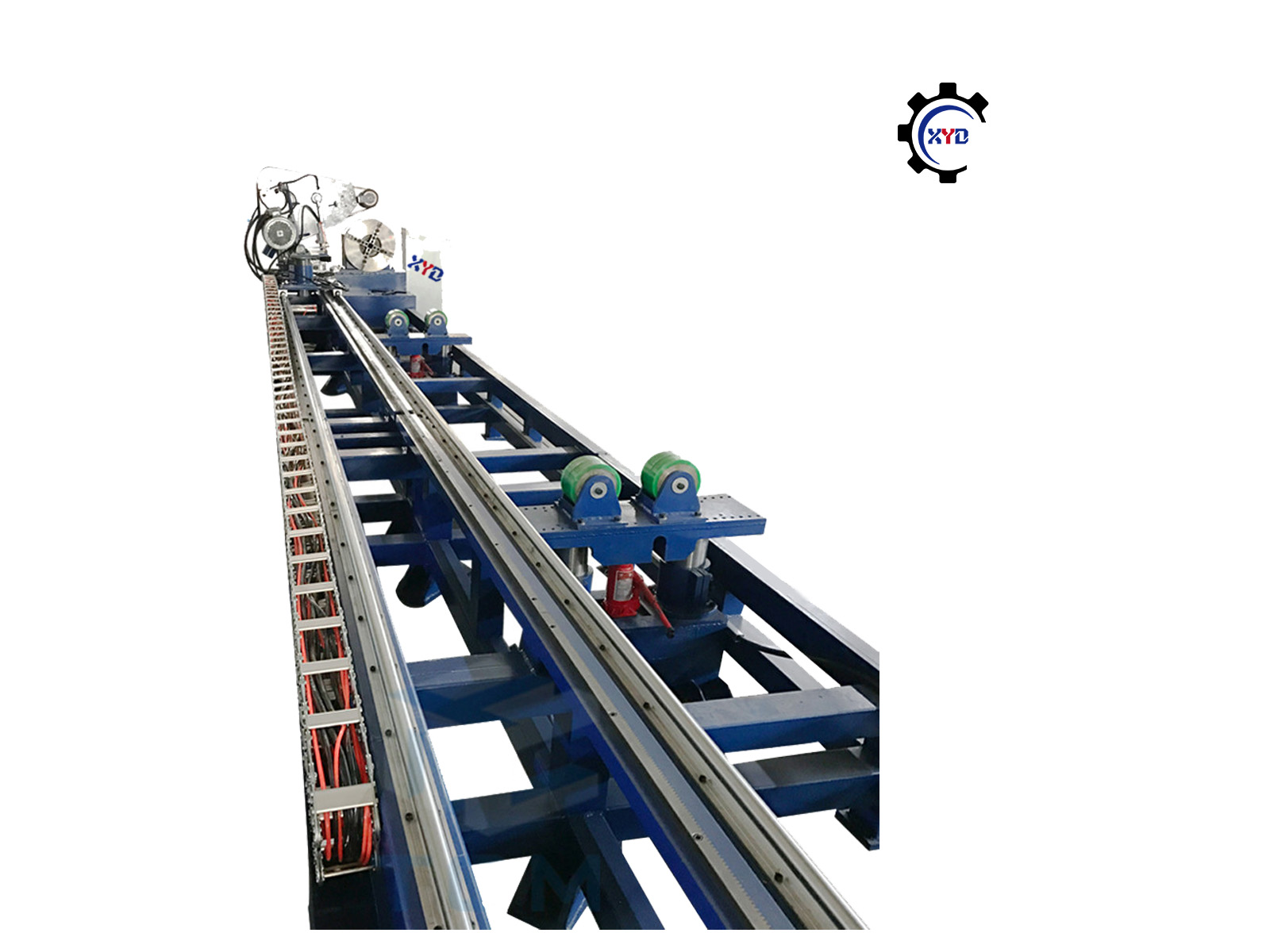

Pipe polishing machine-XYD-YG-01

- Introduction

- Video

1. Product Overview

The Automatic pipe polishing machine is designed for precision exterior surface grinding and linishing of steel welded pipes, seamless pipes, and round solid rods. It can also process hydraulic cylinder exteriors and other cylindrical products, delivering a high-quality polished finish. Equipped with double variable frequency grinding motors (7.5KW each), the TCM-WP supports both grinding wheels and abrasive sanding belts.

Its versatility makes it widely applicable in industries such as pharmaceutical, medical, food processing, water purification, pressure vessels, cosmetics, wastewater treatment, semiconductors, and photovoltaics.

2. Product Features

-

Dual variable frequency grinding motors for stable and adjustable processing speed.

-

Compatible with both grinding wheels and abrasive sanding belts (flap/cloth/emery/nylon wheel).

-

High polishing precision with surface roughness (Ra) ≤ 0.25 μm.

-

Optional water cooling system for better temperature control during polishing.

-

Heavy-duty pipe roller loading capacity from 1 ton to 7 tons.

-

Customizable design with multiple color options (Grey, Green, Blue, Red, Yellow).

-

Suitable for long pipes up to 12 meters in length.

3. Technical Parameters

| Parameter | Specification |

|---|---|

| Max. Pipe Diameter | 40–800 mm |

| Pipe Thickness | 3–10 mm |

| Pipe Length | ≤ 12,000 mm |

| Machine Dimensions (LWH) | 14,500 × 1,200 × 1,200 mm |

| Pipe Roller Max. Loading | 1 Ton / 2 Ton / 5 Ton / 7 Ton (optional) |

| Surface Roughness (Ra) | ≤ 0.25 μm |

| Working Speed | 6–12 m²/h |

| Total Power Input | 22 KW |

| Power Supply | 380V / 415V / 50Hz / 60Hz / 3 Phase or customized |

| Machine Weight | 3,800 kg |

| Color | Grey / Green / Blue / Red / Yellow (customizable) |

| Suitable Polishing Materials | Abrasive sanding belts, grinding wheels (flap/cloth/emery/nylon) |

| Optional Feature | Water cooling system |

4. Processing Scope & Applications

Processing Scope:

-

Steel welded pipes and seamless pipes

-

Round solid bars and steel rods

-

Hydraulic cylinder exteriors

Application Industries:

-

Pharmaceutical & medical equipment manufacturing

-

Food processing machinery

-

Water treatment and purification

-

Pressure vessel manufacturing

-

Cosmetic product containers

-

Wastewater treatment systems

-

Semiconductor and photovoltaic industries

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service