Industrial Polishing & Grinding Machine

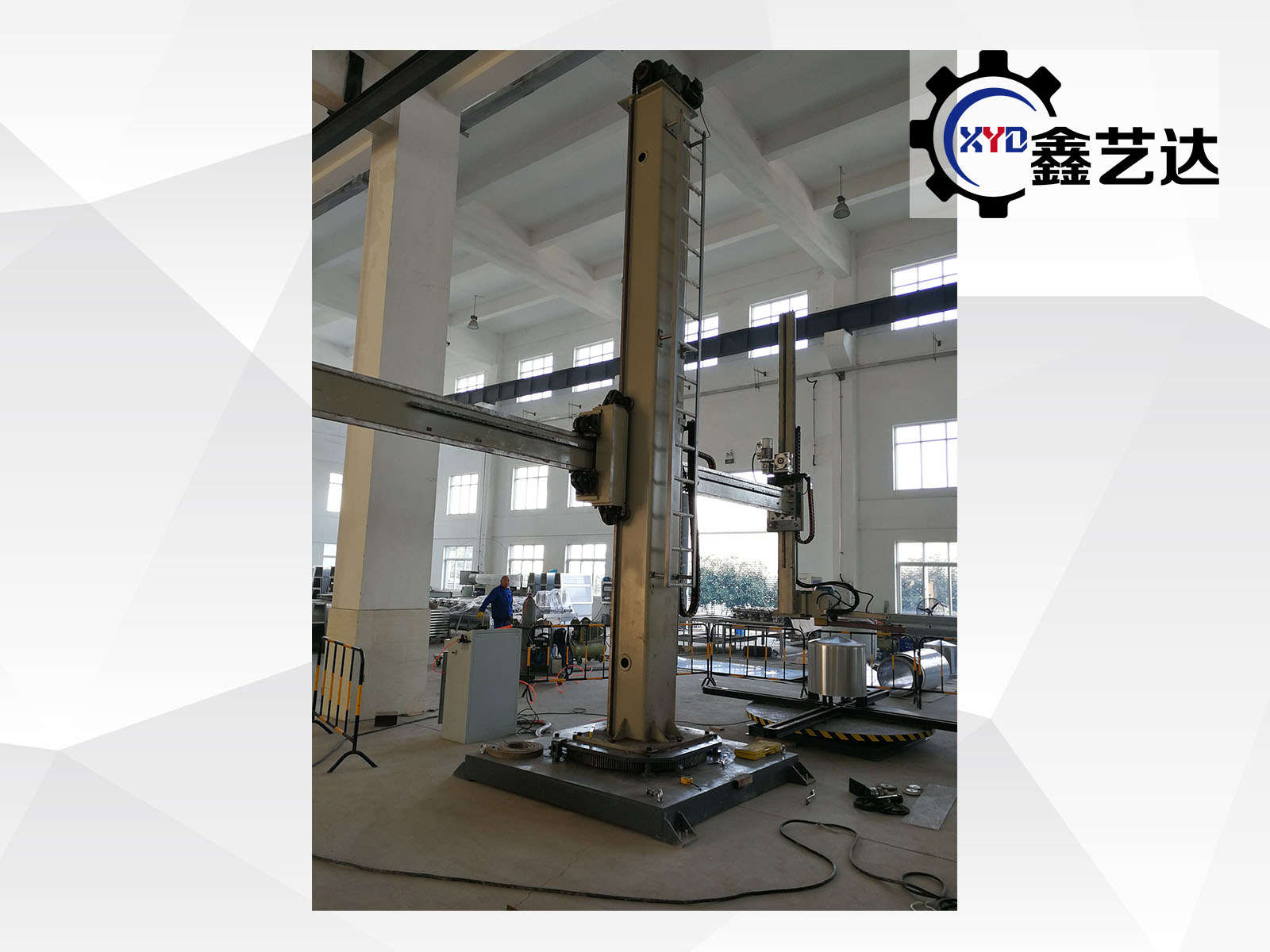

The XYD Industrial Polishing & Grinding Machine is a fully integrated system designed for internal and external surface finishing of stainless steel tanks and dished heads with diameters ranging from φ1000mm to φ5000mm. It supports brushed finishing, semi-polishing, and mirror polishing with high accuracy and efficiency, ideal for industries such as chemical processing, food, pharmaceutical, energy, and shipbuilding. The machine comprises a horizontal beam, column, reinforced base, tank and head polishing heads, rotating worktables, and a centralized control cabinet.

Industrial Polishing & Grinding Machine XYD-CZJ-2

- Introduction

- Video

1. Product Overview

The XYD Industrial Polishing & Grinding Machine is a fully integrated system designed for internal and external surface finishing of stainless steel tanks and dished heads with diameters ranging from φ1000mm to φ5000mm. It supports brushed finishing, semi-polishing, and mirror polishing with high accuracy and efficiency, ideal for industries such as chemical processing, food, pharmaceutical, energy, and shipbuilding.

The machine comprises a horizontal beam, column, reinforced base, tank and head polishing heads, rotating worktables, and a centralized control cabinet.

2. Key Features

-

Fully Automated Motion Control

Equipped with four frequency converters managing vertical, horizontal, and rotational movements. -

Multi-Tool Compatibility

Quick switching between abrasive belts, flap wheels, sisal wheels, and cloth buffs. -

High Surface Accuracy

Achieves surface roughness up to Ra ≤ 0.4μm, suitable for food-grade or mirror-finish requirements. -

Heavy-Duty Rotary Table

Standard 5-ton capacity, customizable up to 20 tons for heavy-duty applications. -

Durable Structural Design

Embedded heavy base ensures high stability during polishing operations.

3. Technical Specifications

| Category | Specification |

|---|---|

| Workpiece Range | φ1000mm–5000mm (tanks and dished heads) |

| Workpiece Height | 2500mm (vertical tank placement) |

| Rotary Table Load | Standard 5 tons, customizable 1–20 tons |

| Total Power | Approx. 12kW |

| Machine Size | 6000 × 800 (embedded base) × 5000 mm |

| Beam Travel | Max. 5000mm effective stroke |

| Motion Drives | 4 frequency inverters (X/Y/Z + rotation) |

| Spindle Motor | 5.5kW (national standard, frequency-controlled) |

| Abrasive Specs | Belt: 2540×50mm; Flap wheel: φ250×50mm; sisal; cloth |

| Surface Finish | Ra ≤ 0.4μm |

| Productivity | 10㎡/hour (continuous operation) |

4. Application Fields

-

Chemical Processing: Polishing of large-capacity stainless steel reactors

-

Food & Pharma: Inner wall polishing for food-grade storage tanks

-

Energy & Storage: LNG or liquid transport tank surface treatment

-

Environmental Systems: Surface grinding for wastewater treatment tanks

-

Shipbuilding & Aerospace: Seam finishing for dished heads and pressure parts

Optional customization available for special materials, robotic integration, or online detection systems.

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service