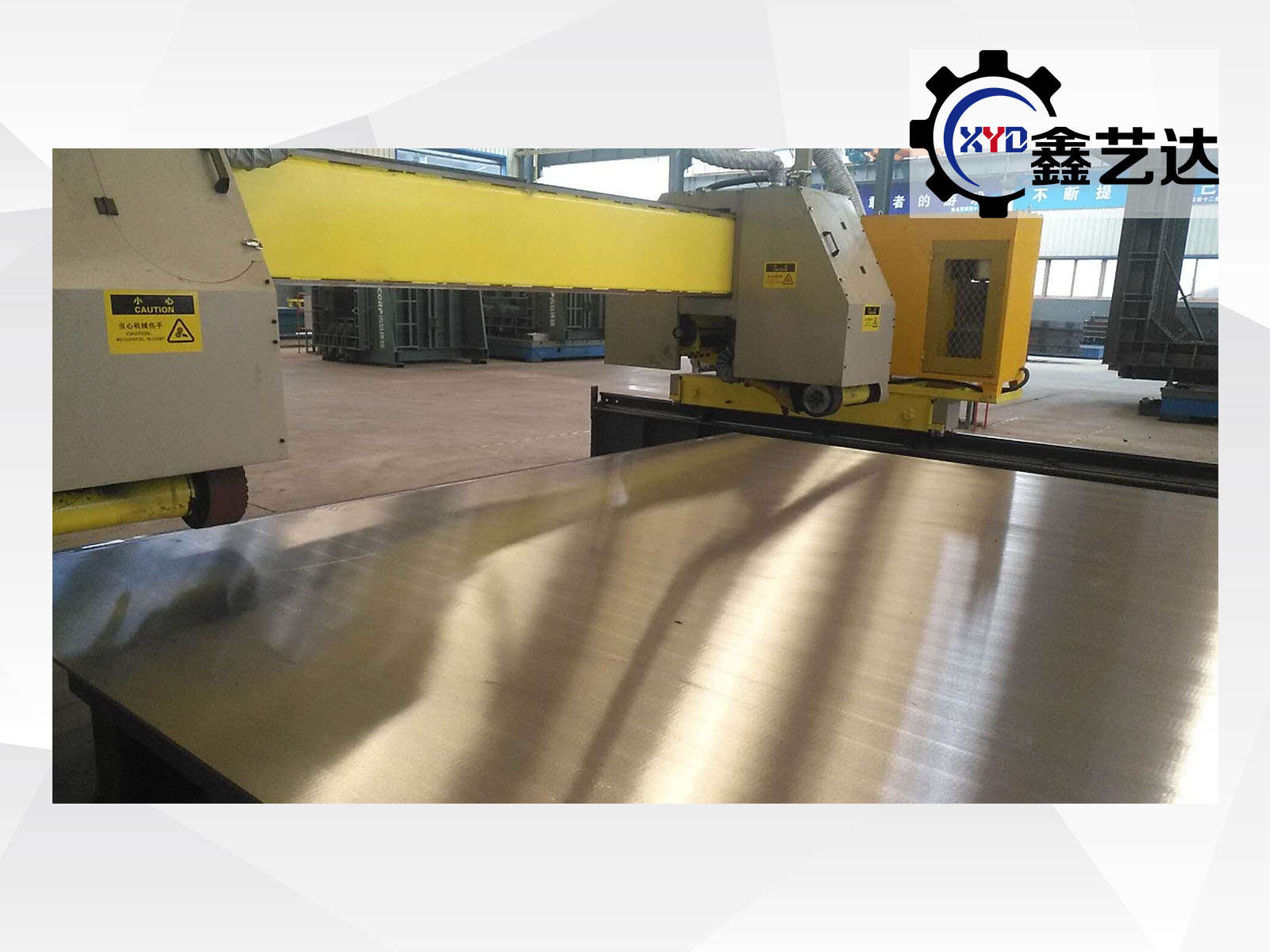

PLC-Controlled Flat Sheet Polishing Machine

The PLC Flat Surface Polishing Machine is a high-performance polishing system designed for mirror finishing of large metal sheets. It features a dual-head structure with water-based polishing, and a circulating cooling water filtration system that reduces thermal deformation during processing. Controlled by PLC programming, the machine allows automated adjustment of polishing parameters such as panel width, length, spraying wax, and water cycles.

PLC-Controlled Flat Sheet Polishing Machine

- Introduction

1. Product Overview

The PLC Flat Surface Polishing Machine is a high-performance polishing system designed for mirror finishing of large metal sheets. It features a dual-head structure with water-based polishing, and a circulating cooling water filtration system that reduces thermal deformation during processing. Controlled by PLC programming, the machine allows automated adjustment of polishing parameters such as panel width, length, spraying wax, and water cycles.

2. Key Features

-

Dual-Head Polishing: Two dual-speed motors for simultaneous or independent operation.

-

Water-Cooled System: Recirculating filtered water system for efficient cooling and environmental protection.

-

Smart PLC Control: Customizable settings for sheet size, water/wax spray timing, and polishing intervals.

-

Precision Installation: Requires high ground flatness (1000:1 ratio) for optimal surface stability.

-

Waterproof Design: All polishing heads and electrical units are waterproof for safe long-term operation.

-

Standardized Track System: Equipped with a 6-meter track (22kg/m) for smooth sheet movement.

3. Technical Specifications

| Item | Specification |

|---|---|

| Machine Weight | 3500 KG |

| Machine Dimensions (L×W×H) | 5200 × 2000 × 1400 mm |

| Polishing Heads | 2 sets, dual-speed motors (11/14 kW) |

| Water Tank Model | HQ150 (150L capacity) |

| Spray Pump / Circulation | 210W / 170W |

| Electrical Control | PLC programmable system |

| Wax & Water Spray System | Adjustable spray intervals, 2 wax guns, 1 wax bucket |

| Rail System | 6-meter track, 22kg/m (supplied by seller) |

| Installation Requirement | Ground flatness 1000:1 (by buyer) |

| Efficiency | Polishing 1.5m × 6m panel to mirror finish: ~1h 40min |

4. Applications

-

Stainless steel sheet mirror finishing

-

Decorative metal panel polishing

-

Oxide removal on large metal plates

-

Precision panel surface finishing

-

Ideal for kitchenware, elevators, façade panels

Contact information

QR code

QQ Customer Service

QQ Customer Service