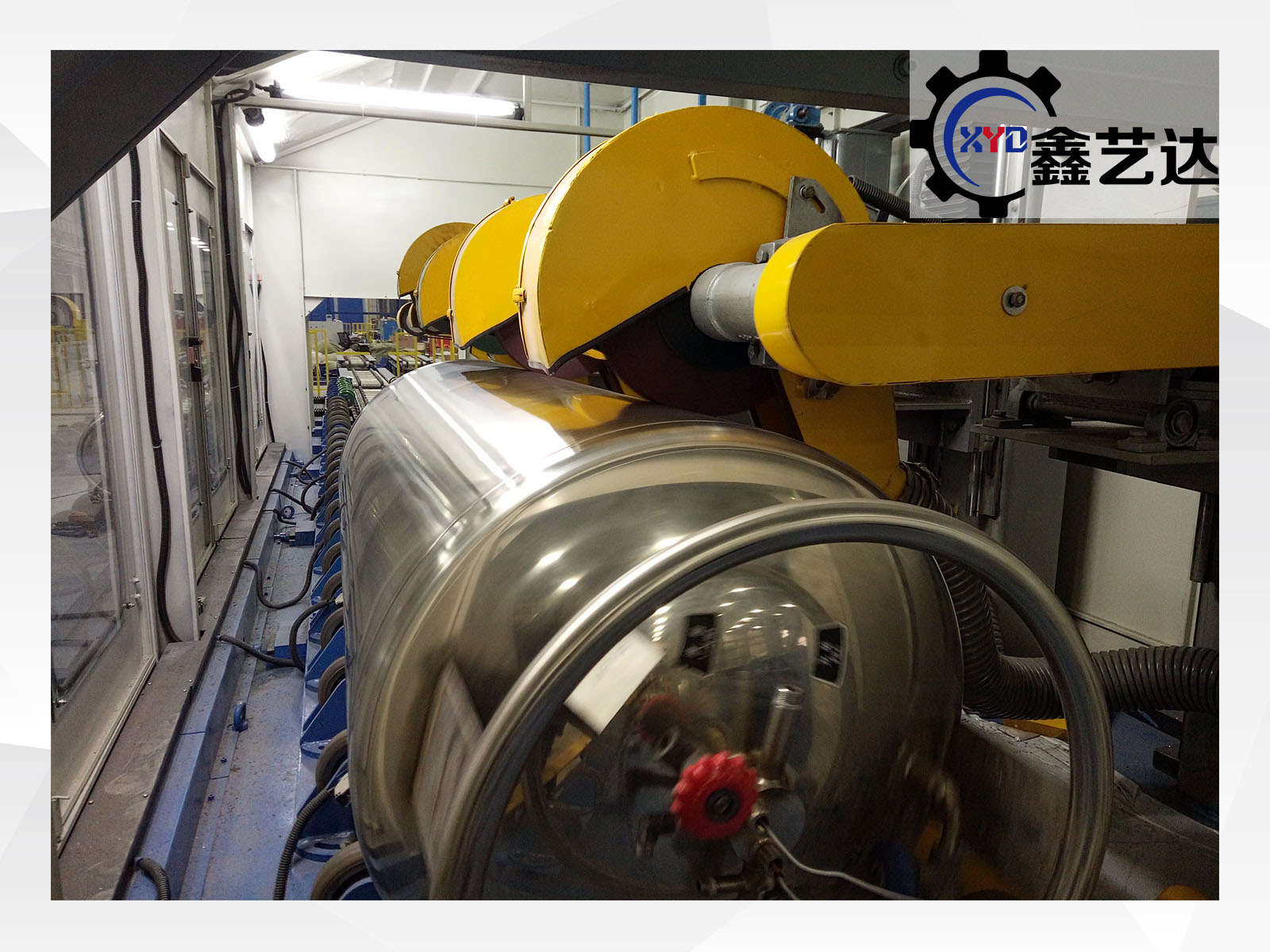

LNG Pass-Through Polishing Machine

The LNG Through-Type Polishing Machine is an automatic surface finishing system designed for external polishing of LNG cylinder shells. Integrated seamlessly with a conveying line, the cylinders are automatically loaded into the machine, where horizontal spiral feed ensures continuous polishing. Equipped with constant-pressure polishing heads, motorized screw lift adjustments, and sealed dust-control enclosures, this system delivers high-speed, high-precision surface finishing for a wide range of cylinder diameters.

LNG Pass-Through Polishing Machine XYD-LNG

- Introduction

- Video

1. Product Overview

The LNG Through-Type Polishing Machine is an automatic surface finishing system designed for external polishing of LNG cylinder shells. Integrated seamlessly with a conveying line, the cylinders are automatically loaded into the machine, where horizontal spiral feed ensures continuous polishing. Equipped with constant-pressure polishing heads, motorized screw lift adjustments, and sealed dust-control enclosures, this system delivers high-speed, high-precision surface finishing for a wide range of cylinder diameters.

2. Key Features

-

Fully Automated Pass-Through Operation: Cylinders are transported in spiral motion while being polished, ideal for mass production.

-

Constant-Pressure Head: Pneumatically adjusted to ensure uniform surface polishing without overgrinding.

-

Flexible Diameter Adjustment: Motor-driven lift for polishing head, manual follower wheel adjustment to suit different cylinder diameters.

-

Versatile Polishing Media: Compatible with abrasive belts, flap wheels, wool wheels, nylon disks, cloth wheels.

-

Enclosed Safety Housing: Full enclosure with transparent window and dust extraction ports to ensure safety and cleanliness.

-

Electrical and Mechanical Safety: Top and bottom limit protections prevent overtravel and protect components.

3. Technical Specifications

| Item | Specification |

|---|---|

| Total Power Input | Approx. 30KW |

| Dimensions (L×W×H) | 9200 × 1500 × 1500 mm |

| Machine Weight | 4500 KG |

| Surface Roughness Accuracy | Ra ≤ 0.3μm (achieved by stepwise polishing) |

| Polishing Materials | Abrasive belts, flap wheels, wool pads, nylon, cloth wheels |

| Workpiece Diameter Range | φ506–656mm, reserved up to φ800mm |

| Workpiece Length | 2300mm (loading/unloading rack 2m each) |

| Max Workpiece Weight | ≤ 300 KG |

| Conveyor Speed | 8 m/min |

| Pressure Adjustment | Regulated via pressure valve |

| Safety Protection | Electrical and mechanical travel limits |

4. Applications

-

LNG cylinder outer surface polishing

-

Horizontal pressure vessel polishing

-

Stainless steel tank finishing

-

High-efficiency tube and shell polishing

-

Mass production of cylindrical metal polishing

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service