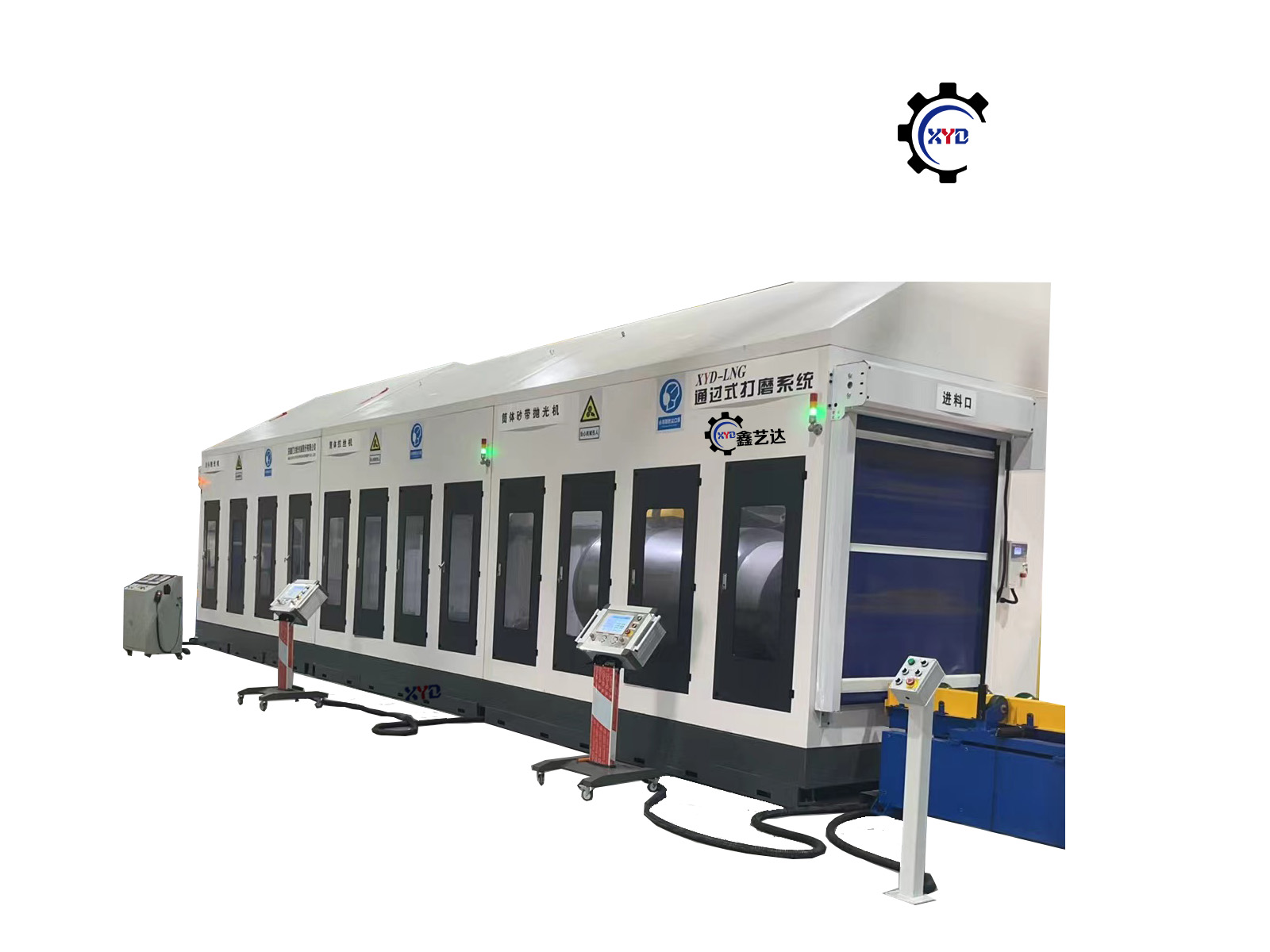

Automatic LNG Cylinder Pass-Through Polishing Line

The LNG vehicle cylinder polishing system is located at the rear end of the flexible production line, featuring a multi-station grinding head assembly that polishes welds, cylinder bodies, and heads.

Automatic LNG Cylinder Pass-Through Polishing Line XYD-LNG-1

- Introduction

- Video

1. Product Overview

The LNG Cylinder Pass-Through Polishing System is an automated polishing solution designed for liquefied natural gas storage cylinders. It performs high-precision polishing and brushing on cylinder bodies and end caps. The system features enclosed grinding covers and a dust collection system, ensuring safe, environmentally friendly operation while enhancing production efficiency and surface quality.

2. Product Features

| Feature | Description |

|---|---|

| Fully Automated Pass-Through | Automatic loading and sequential processing through weld seam polishing, cylinder polishing, brushing, and end cap polishing stations |

| High-Precision Polishing | Achieves surface roughness Ra ≤ 0.8μm, ensuring cylinder aesthetics and weld smoothness |

| Enclosed Safety Design | Enclosed grinding area with dust collection system to minimize dust and operational risks |

| High Efficiency | Production cycle time of 20 minutes per piece, significantly improving throughput |

| Flexible Adaptation | Suitable for LNG cylinders with diameter 580~1500mm and length ≤2500mm |

3. Technical Specifications

| Parameter | Specification |

|---|---|

| Effective Polishing Length | ≤2500mm |

| Effective Polishing Diameter | 580~1500mm |

| Surface Roughness | Ra ≤0.8μm |

| Production Cycle | 20 minutes per piece |

| Key Stations | Loading, weld seam polishing, cylinder polishing, brushing, end cap polishing, unloading |

| Safety Measures | Enclosed cover + Dust collection system |

4. Processing Scope & Applications

Applicable for LNG cylinders, pressure vessels, and similar metal cylinders requiring surface polishing and brushing. Widely used in petrochemical, energy, and gas storage industries, especially where high surface finish, weld aesthetics, and safety standards are required.

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service