CNC Equipment Data Collection and MES Integration Solution

Xinyida helps Hangzhou customers integrate equipment data — Edge computing and AI large models empower MES systems to achieve digital upgrades in workshops

CNC Equipment Data Collection and MES Integration Solution XYD-MES

- Introduction

Project Background

To comprehensively improve equipment utilization and production management at a Hangzhou client’s workshop, the existing production equipment requires intelligent upgrades and data integration. The objectives of this project are:

-

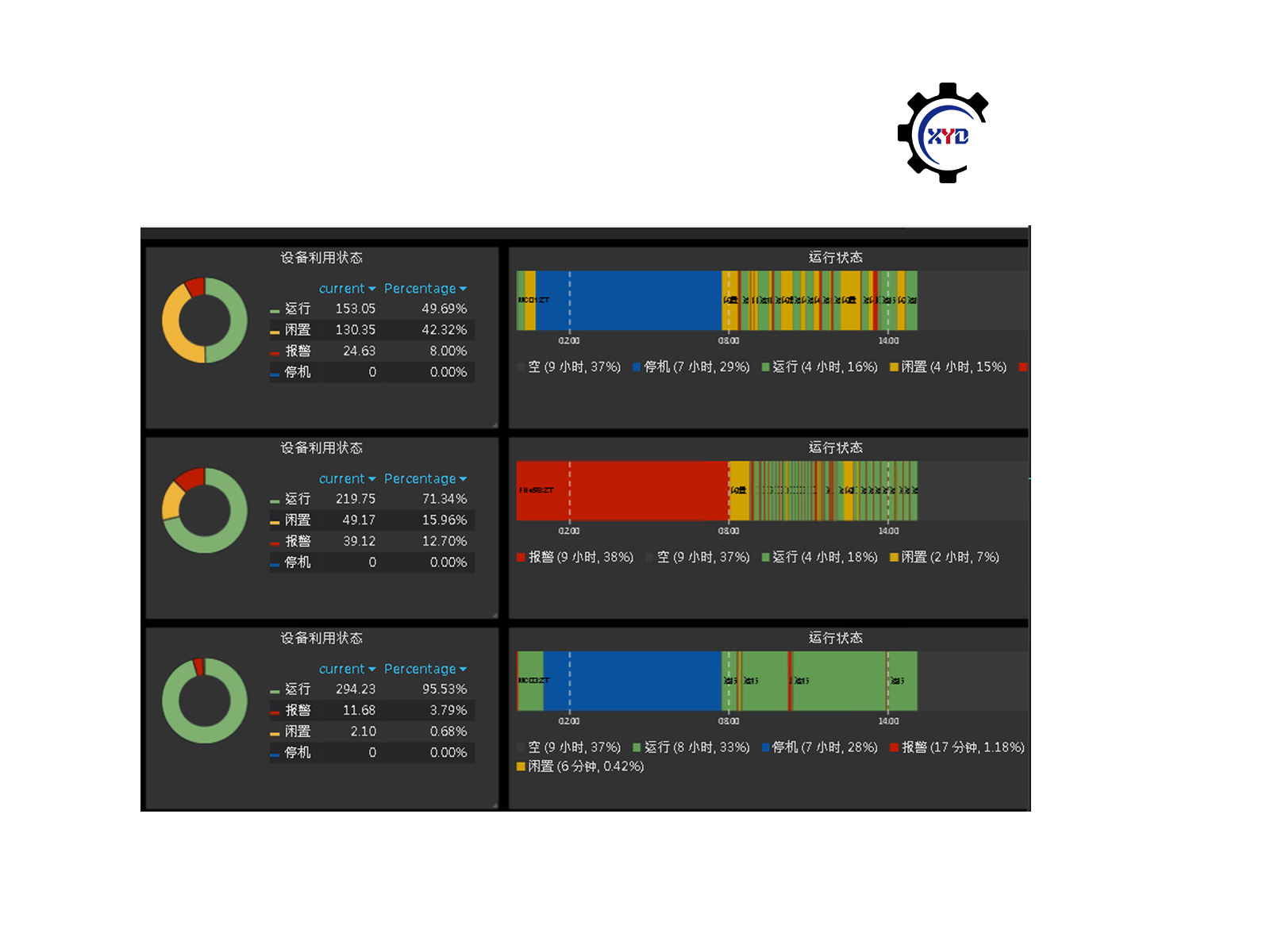

Enhance equipment utilization: Reduce idle and waiting time through real-time collection of equipment operational status.

-

Accurately analyze bottlenecks: Identify constraints in CNC machine operations based on collected data to optimize production cycles.

-

Scientifically quantify machining parameters: Record and analyze core parameters such as feed rate, spindle speed, power, and ratio in real time.

-

Monitor equipment health in real time: Provide early warnings for abnormal conditions to ensure safe and stable production.

The devices included in the data integration scope are:

-

CNC machines

-

Welding equipment

-

Polishing equipment

-

Other critical production equipment

Total: 20 units

Overall Integration Solution

Implementing Party: Anhui Xinyida Polishing Machinery Co., Ltd. (Project Lead)

Technical Approach:

-

Edge Computing Gateway Deployment

-

Install edge computing gateways on-site to integrate data from multi-protocol, multi-brand equipment and standardize the data.

-

-

Network Communication Module Configuration

-

Use wired/wireless network modules to ensure stable communication between equipment and the data gateway.

-

-

Data Encryption and API Integration

-

Use the API Library to encrypt and package collected operational data, ensuring security and integrity during transmission.

-

-

MQTT IoT Server Integration

-

Transmit encrypted data to the MQTT IoT server, achieving efficient, low-latency data transmission.

-

-

AI Large-Model Analysis and MES System Integration

-

The AI model analyzes the aggregated data, generates visual reports and optimization suggestions.

-

Both analysis results and raw data are synchronized to the MES system (Manufacturing Execution System) for production planning, process optimization, and maintenance decision-making.

-

Note:

The MES system (Manufacturing Execution System) is a production information management system for the shop floor, enabling production scheduling, quality traceability, process management, and equipment status monitoring.

Contact information

QR code

QQ Customer Service

QQ Customer Service