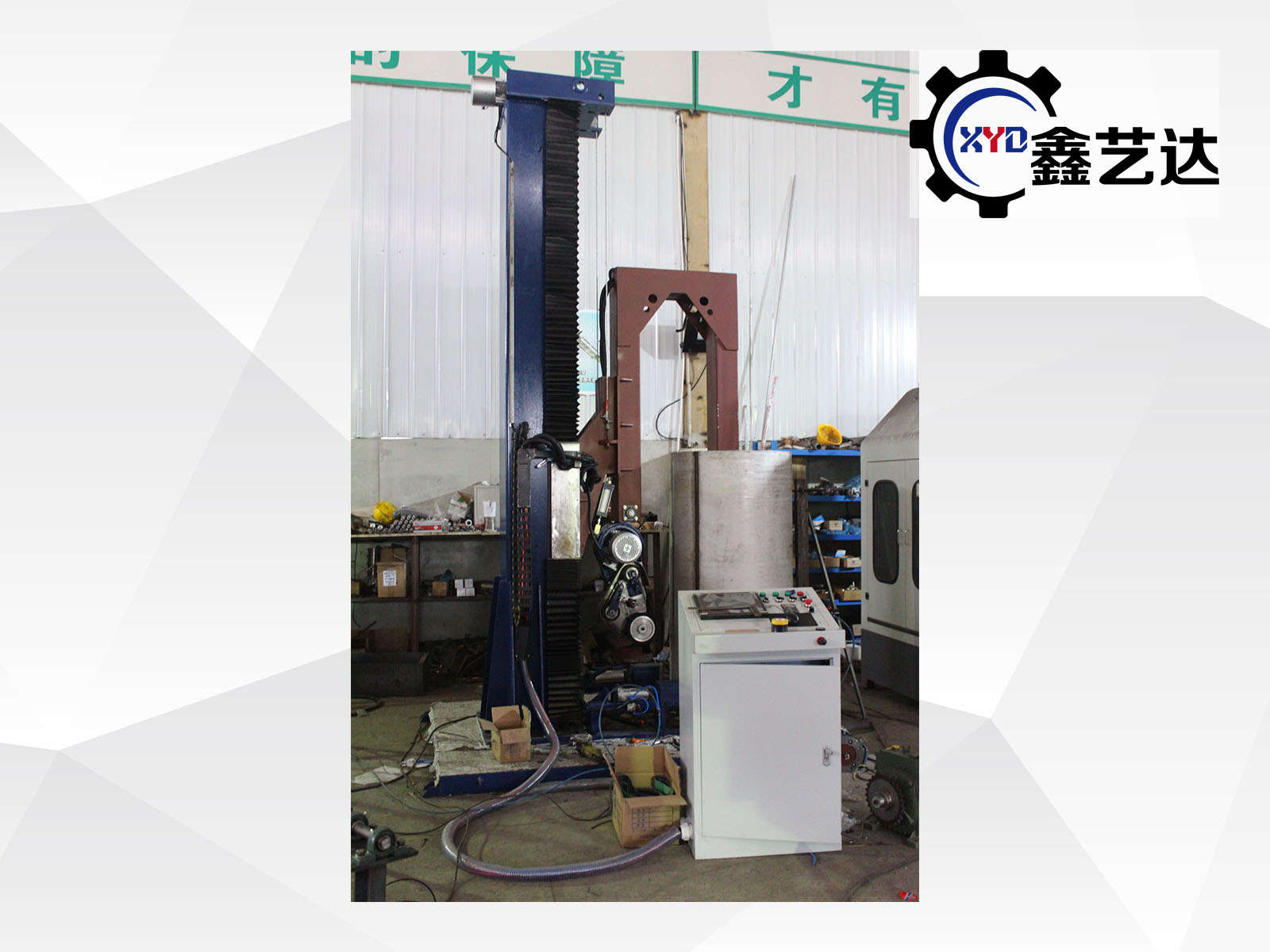

Weld Seam Polishing Machine

The PLC-controlled weld seam polishing machine is specially designed for internal and external polishing of vertical tank longitudinal welds. It supports cylindrical workpieces with diameters from φ750mm to φ4000mm, lengths 1219mm to 2000mm, and up to 5 tons in weight. Featuring PLC automation, interchangeable abrasive belt/flap wheel polishing heads, a high-definition camera, and an industrial monitor, this machine ensures safe, precise, and efficient polishing of weld seams. CE certified for international compliance.

Weld Seam Polishing MachineXYD-HF-PLC

- Introduction

1. Product Overview

The PLC- controlled Weld Seam Polishing Machine is specially designed for polishing the inner and outer longitudinal weld seams of vertical tanks. It is suitable for stainless steel or carbon steel tanks with a diameter of φ750mm to φ4000mm, length of 1219mm to 2000mm, and weight up to 5 tons.

Equipped with PLC automatic control, brake motor drive, screw lifting system, and HD camera monitoring, the machine ensures precise, safe, and efficient grinding and mirror polishing operations. Fully compliant with CE certification standards, it is widely used in pressure vessels, stainless steel storage tanks, chemical tanks, food-grade tanks, and energy equipment.

2. Product Features

| Feature | Description |

|---|---|

| PLC Automatic Control System | Supports lifting, start/stop, and speed adjustment; mobile control cabinet for flexible operation |

| Dual Independent Grinding Heads | Separate heads for internal and external seams; interchangeable abrasive belts and flap wheels for coarse or fine polishing |

| High-Efficiency Aluminum Alloy Motor | 2.2KW vertical secondary motor from Wannan; stable performance, low noise, and long service life |

| HD Camera Monitoring System | Built-in HD camera and industrial monitor for real-time internal polishing observation |

| Multiple Safety Protections | Screw rods with protective covers, linear rails with safety mesh for operator safety |

| Compact & Easy Maintenance | Space-saving design with centralized core components for convenient servicing |

3. Technical Specifications

| Item | Specification |

|---|---|

| Power Supply | 415V / 50Hz / 3-phase; control voltage 24~48V AC (CE compliant) |

| Dimensions | 2000mm × 1600mm × 3500mm |

| Workpiece Diameter Range | φ750mm ~ φ4000mm |

| Workpiece Length Range | 1219mm ~ 2000mm |

| Max. Workpiece Weight | ≤ 5 Tons |

| Grinding Head Motor Power | 2.2KW (Wannan vertical aluminum alloy secondary motor) |

| Abrasive Materials | Interchangeable abrasive belt / flap wheel, belt width 30mm |

| Control System | PLC program + mobile control cabinet + camera monitoring system |

4. Processing Scope & Applications

This machine is ideal for inner and outer polishing of longitudinal weld seams in metal cylindrical tanks, especially for products requiring high surface finish and aesthetic weld appearance, including:

-

Stainless Steel Storage Tanks (food-grade, pharmaceutical-grade)

-

Pressure Vessels (chemical, petrochemical, energy)

-

Food/Chemical Tanks

-

LNG Cylinders and Energy Equipment

Widely applied in pharmaceutical, food, beverage, petrochemical, energy, and environmental industries, meeting strict hygiene and structural strength requirements.

Contact information

QR code

QQ Customer Service

QQ Customer Service