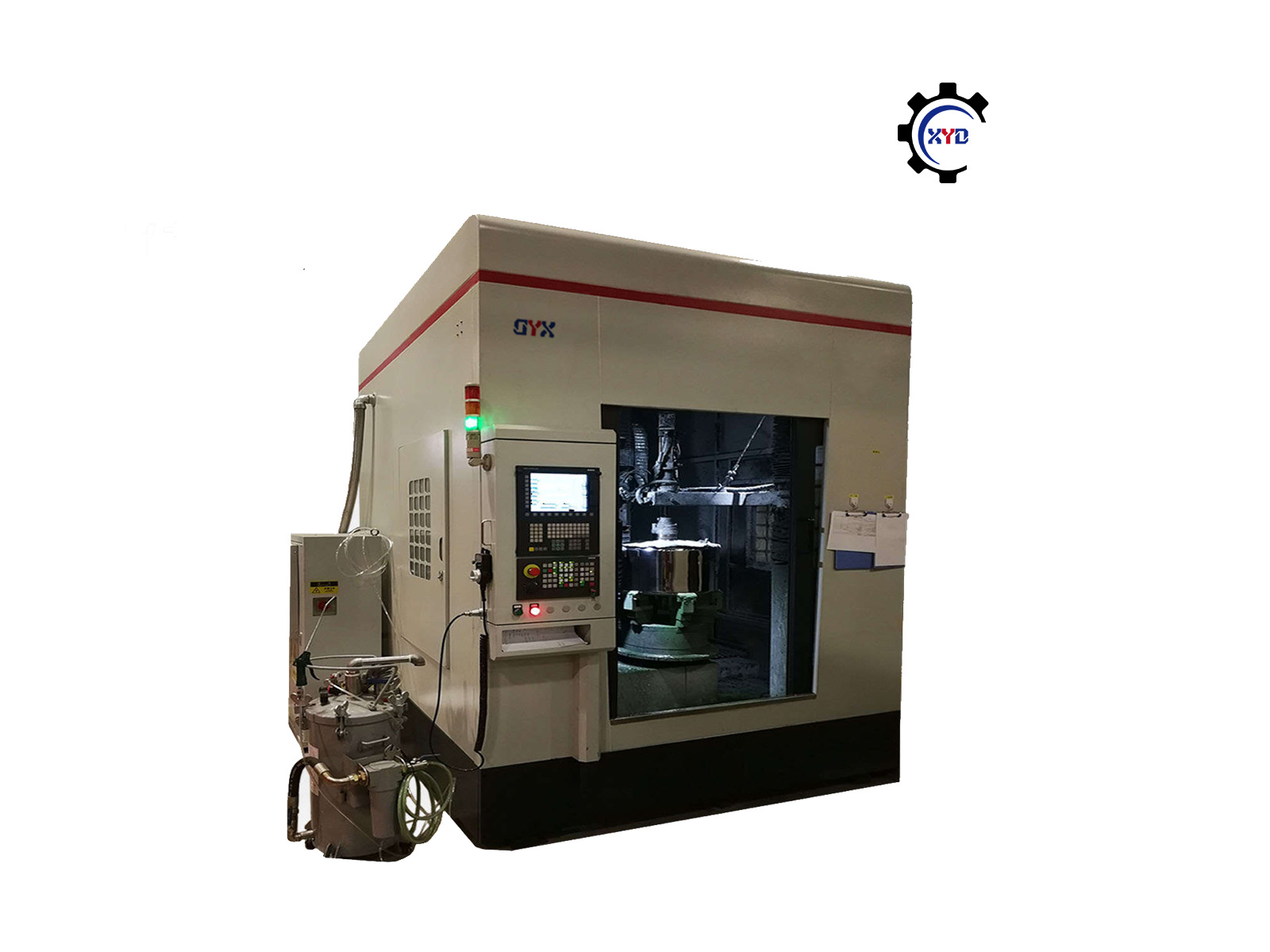

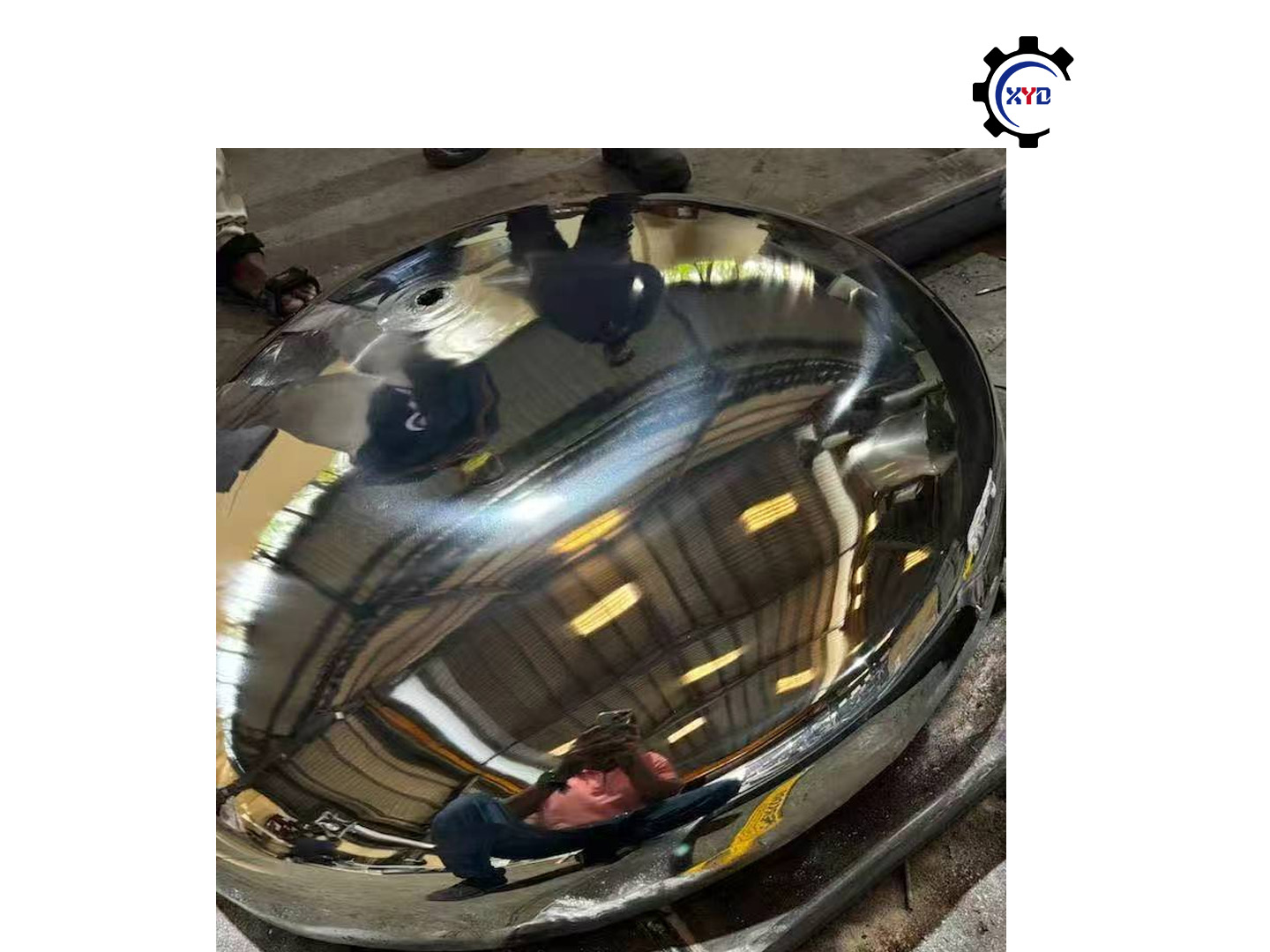

5-Axis CNC polishing machine(high precision CNC mirror polishing machine)

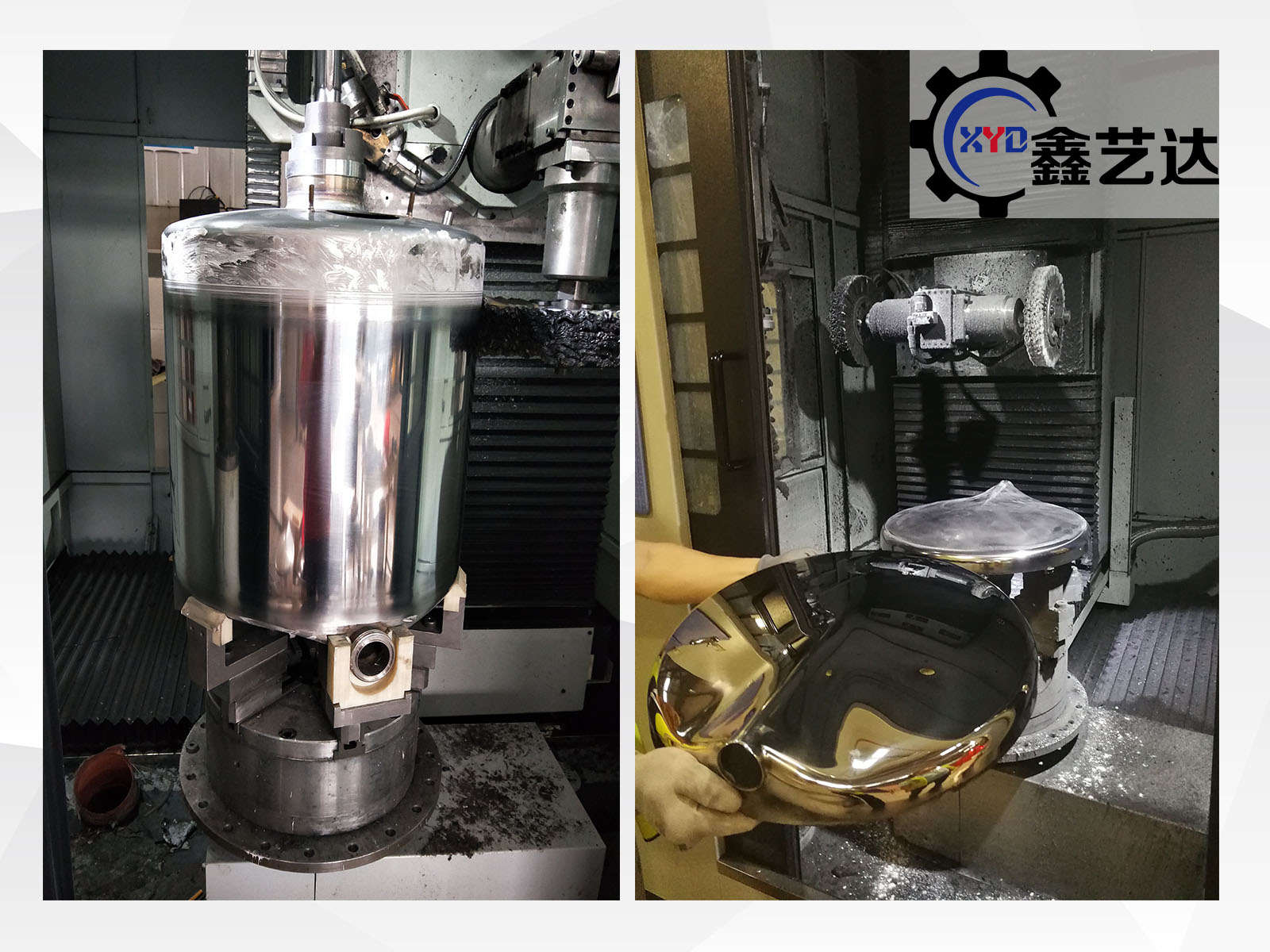

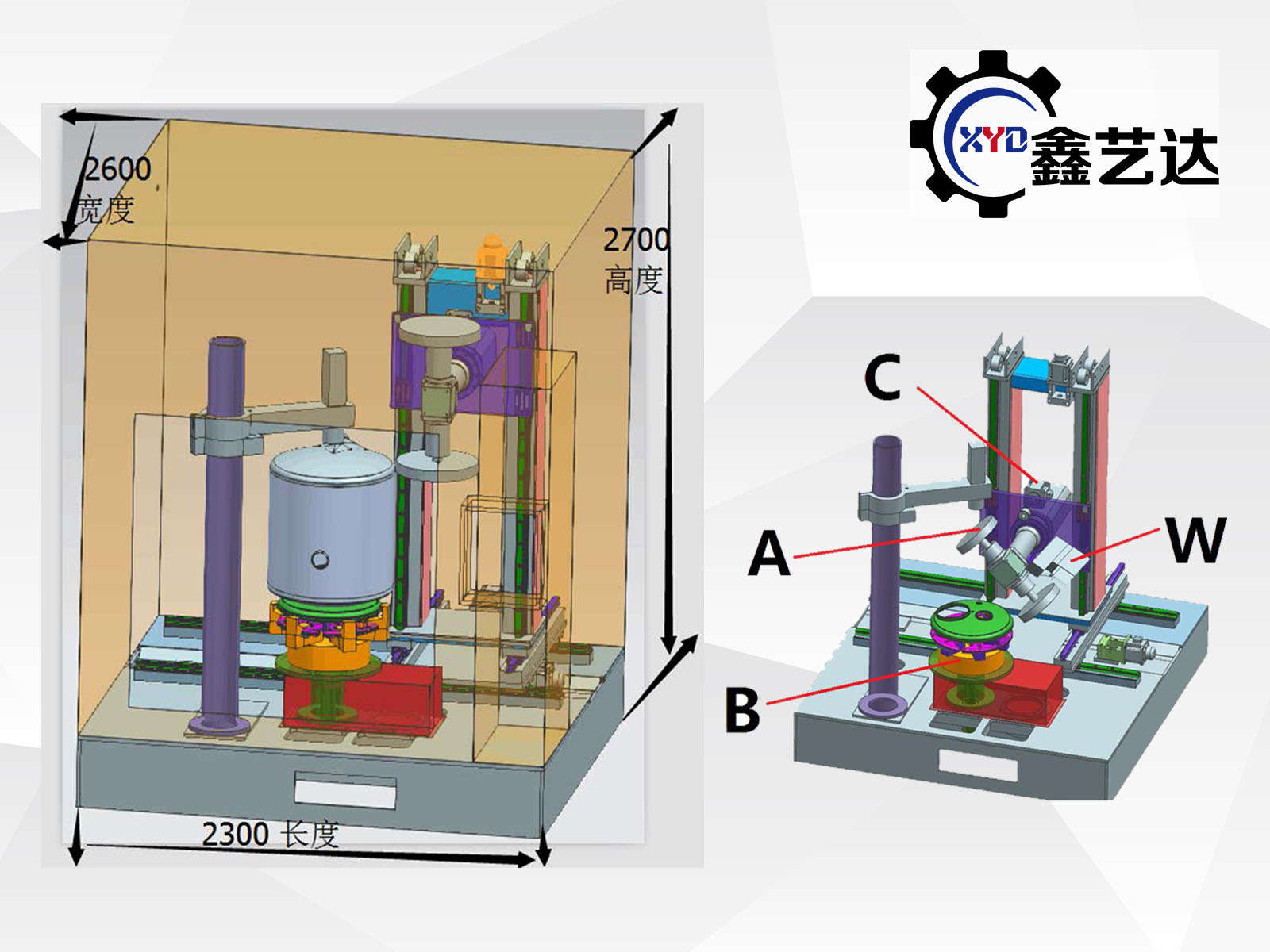

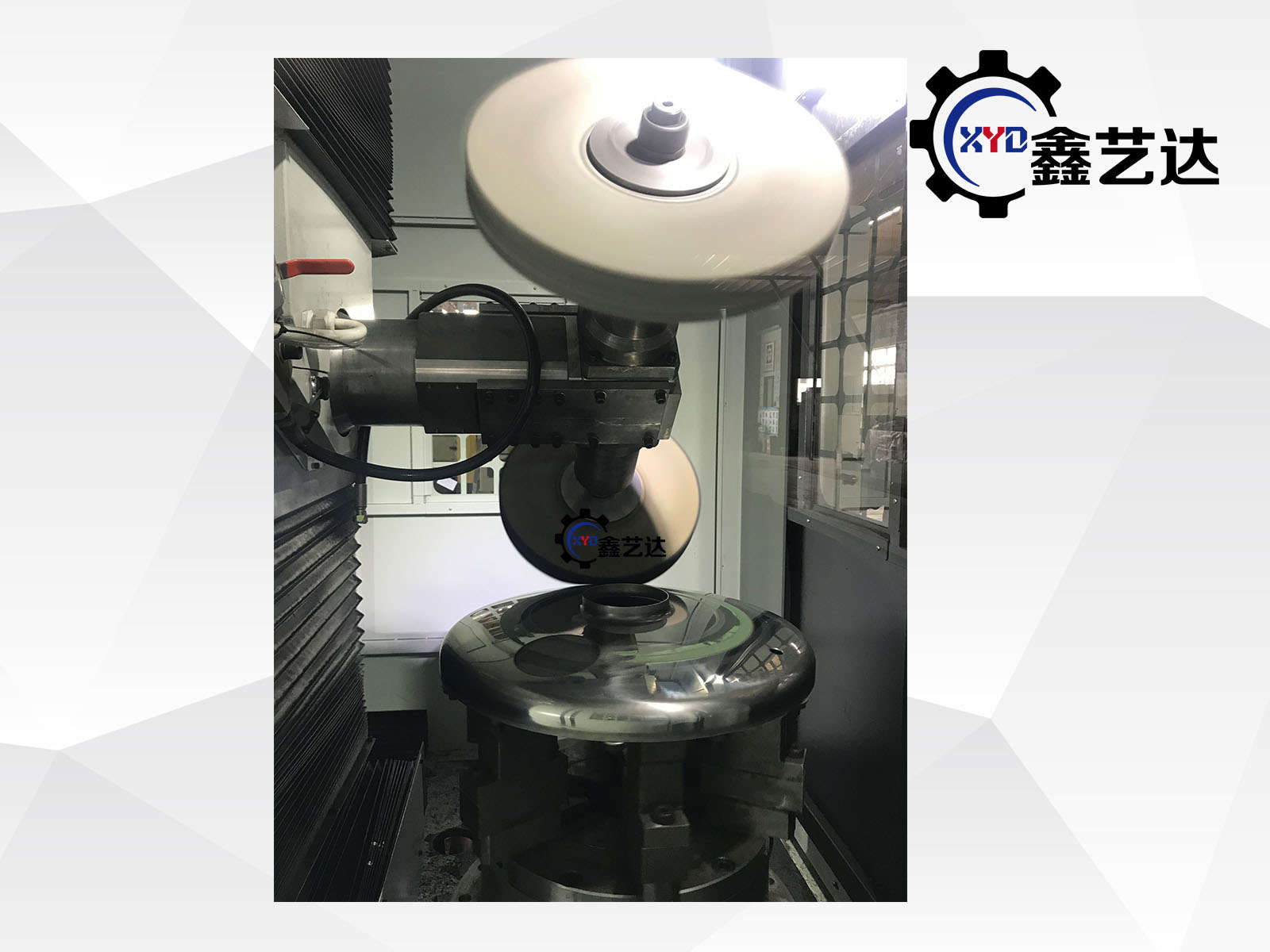

The equipment is mainly used for polishing stainless steel cylinders, cones and heads and connecting parts of the internal and external walls of the grinding and polishing, by the cross host, grinding head assembly, cooling circulation system, electrical control system, pneumatic system workpiece turntable composition. This system throw head motor, turntable and other related components are designed according to the wet polishing process, wet belt polishing so that the grinding dust in the water rinse, out of the surface of the workpiece, the water can be recycled after a simple precipitation, filtration, to achieve zero pollution, in line with the national environmental protection requirements, the use of the grinding spindle servo rotary technology, to improve the efficiency of the grinding at the same time to improve the effect of the surface polishing.

5-Axis CNC polishing machine High precision CNC mirror polishing machine XYD-CNC-5A-DeLaval Custom Model

- Introduction

- Video

1. Product Overview(DeLaval Custom Model)

The 5-Axis CNC Mirror Polishing Machine is a fully automated and precision-engineered system tailored for high-end stainless steel components. This Laval customized version features military-grade explosion-proof design, ideal for environments with flammable polishing dust. Equipped with the Siemens 828D CNC system, it achieves Ra≤0.1μm mirror finish within 18–25 minutes per workpiece, ensuring surface consistency above 98%. Designed for pharmaceutical, food-grade, and precision machinery applications that demand ultra-clean, high-gloss surfaces.

2. Key Features

| Feature | Highlights |

|---|---|

| 8K Mirror Finish | Surface roughness ≤0.1μm with uniform polishing texture |

| Explosion-Proof Design | IP65 spindle motor + 6 IP54 dustproof servo motors |

| High-Speed CNC Control | Siemens 828D system, 18–25 min/piece polishing cycle |

| Enclosed Dust Collection | Custom dust-free design for cleanroom compliance |

| Production Consistency | Batch surface quality consistency over 98% |

3. Technical Specifications

1. Machine Parameters

| Item | Specification |

|---|---|

| Dimensions | 2300×2600×2700mm |

| CNC Control | Siemens 828D |

| Drive System | 1×IP65 explosion-proof + 6×IP54 dustproof motors |

| Protection Grade | Full explosion-proof housing + motor dust covers |

2. Workpiece Performance

| Item | Details |

|---|---|

| Raw Material | Stainless Steel 2B surface (initial Ra≈0.3–0.5μm) |

| Polishing Time | 18–25 minutes per workpiece |

| Surface Finish | 8K Mirror (Ra≤0.1μm), uniform finish |

| Compatible Material | 304 / 316L Stainless Steel |

3. Process Advantages

-

Multi-axis compensation for curved surface matching

-

Adaptive pressure control ensures polishing consistency

-

Data tracking: Polishing parameters recorded per unit

-

Optional AI Vision for surface quality detection (custom)

4. Performance Comparison

| Metric | Manual Polishing | This Equipment |

|---|---|---|

| Time per Piece | 60–90 min | 18–25 min |

| Surface Roughness | Ra≈0.2–0.3μm | Ra≤0.1μm |

| Texture Uniformity | <70% | >98% |

4. Application Scope & Industries

Applicable Workpieces:

-

Stainless tank heads, shells, cones with curved surfaces

-

Mirror finish polishing for critical hygienic environments

-

Supports integration into automated production lines

Target Industries:

-

Pharmaceutical-grade stainless container production

-

Food-grade equipment polishing

-

Mirror finishing of instrument enclosures

-

Pressure vessels and special equipment manufacturing

-

Explosion-proof and dust-controlled workshops

Video Play

Contact information

QR code

QQ Customer Service

QQ Customer Service