Digital upgrade of Hangzhou workshop

Publish time:2025-08-09 22:15:22

Publish time:2025-08-09 22:15:22  Popularity:0

Popularity:0- Case introduction

In the era of smart manufacturing, maximizing equipment utilization and accessing real-time production data have become crucial for enhancing competitiveness. Recently, Anhui Xinyida Polishing Machinery Co., Ltd. partnered with a client in Hangzhou to launch a data integration project for 20 CNC machines, welding equipment, and polishing equipment, aiming to significantly improve workshop efficiency and production management.

The project’s core objectives include:

-

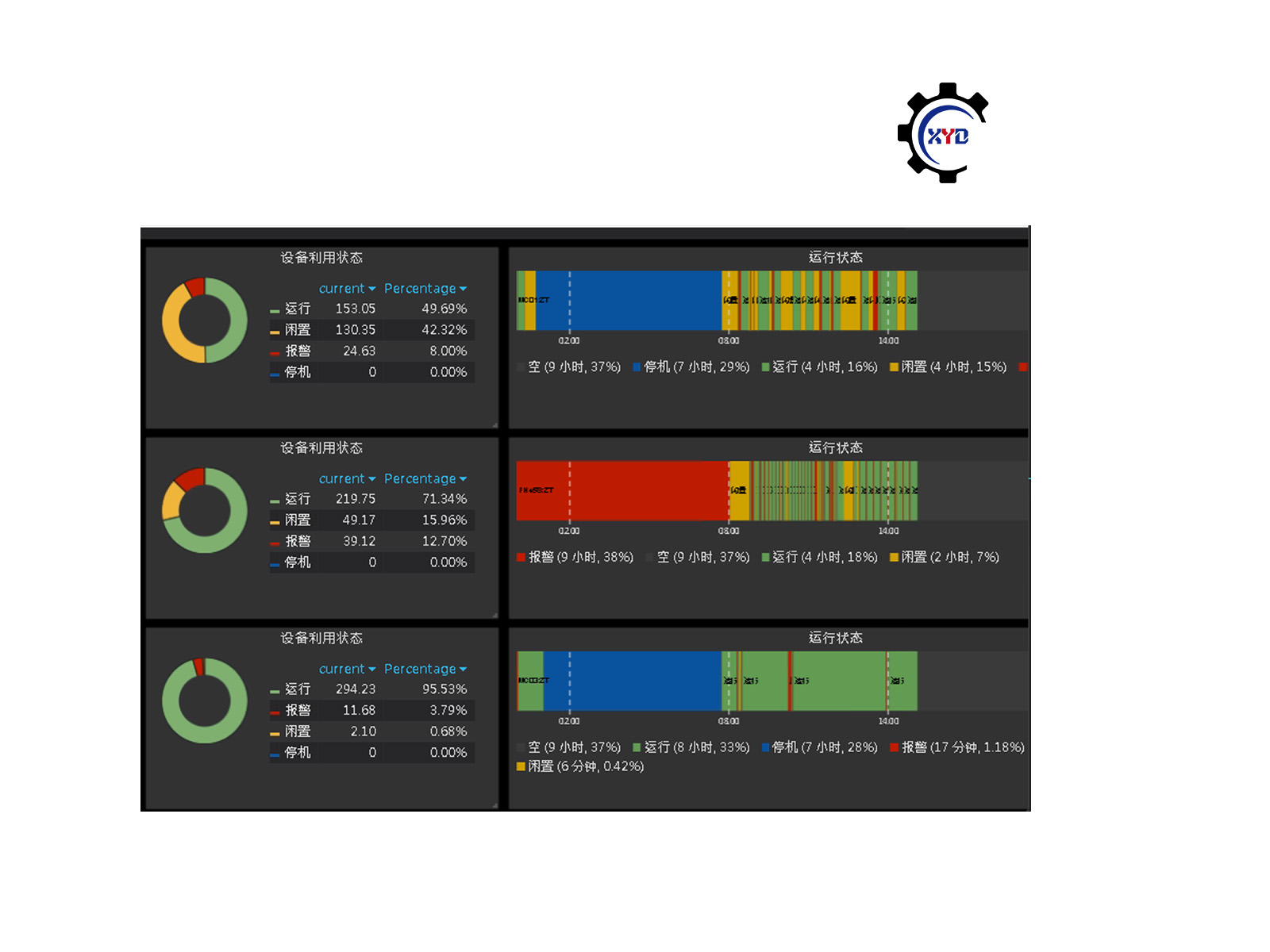

Enhancing equipment utilization: Real-time monitoring and analysis of machine availability to identify bottlenecks.

-

Scientific process parameter measurement: Collecting key machining data such as feed rate, spindle speed, power, and multipliers to optimize manufacturing processes.

-

Ensuring production stability: Capturing operational and health status data in real-time to enable early warnings and reduce downtime risks.

The integration solution involves deploying edge computing gateways and network modules, using an API Library to aggregate data, encrypting and transmitting it to an MQTT IoT server, and then processing it through an AI large model for integration into the client’s MES (Manufacturing Execution System). The MES platform will enable full digitalization of processes from production scheduling and process execution to equipment management.

This collaboration not only builds a secure and efficient data collection and analysis framework for the Hangzhou client but also lays a solid foundation for future smart factory construction. Xinyida remains committed to leveraging its expertise in automation and intelligent equipment to drive digital transformation for more manufacturing enterprises.

Contact information

QR code

QQ Customer Service

QQ Customer Service